Page 33 - SKF-SPEEDI-SLEEVE

P. 33

Designs and features Using LDSLV designs Installation

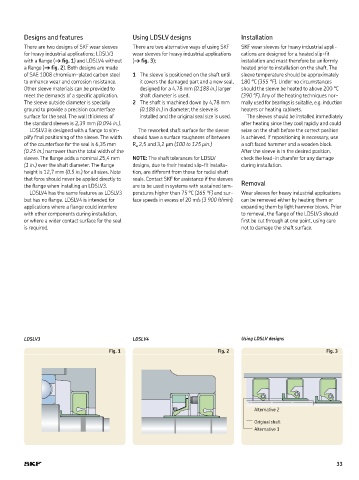

There are two designs of SKF wear sleeves There are two alternative ways of using SKF SKF wear sleeves for heavy industrial appli-

for heavy industrial applications; LDSLV3 wear sleeves for heavy industrial applications cations are designed for a heated slip-fit

with a flange († fig. 1) and LDSLV4 without († fig. 3); installation and must therefore be uniformly

a flange († fig. 2). Both designs are made heated prior to installation on the shaft. The

of SAE 1008 chromium-plated carbon steel 1 The sleeve is positioned on the shaft until sleeve temperature should be approximately

to enhance wear and corrosion resistance. it covers the damaged part and a new seal, 180 °C (355 °F). Under no circumstances

Other sleeve materials can be provided to designed for a 4,78 mm (0.188 in.) larger should the sleeve be heated to above 200 °C

meet the demands of a specific application. shaft diameter is used. (390 °F). Any of the heating techniques nor-

The sleeve outside diameter is specially 2 The shaft is machined down by 4,78 mm mally used for bearings is suitable, e.g. induction

ground to provide a precision counterface (0.188 in.) in diameter, the sleeve is heaters or heating cabinets.

surface for the seal. The wall thickness of installed and the original seal size is used. The sleeves should be installed immediately

the standard sleeves is 2,39 mm (0.094 in.). after heating since they cool rapidly and could

LDSLV3 is designed with a flange to sim- The reworked shaft surface for the sleeve seize on the shaft before the correct position

plify final positioning of the sleeve. The width should have a surface roughness of between is achieved. If repositioning is necessary, use

of the counterface for the seal is 6,35 mm R a 2,5 and 3,2 µm (100 to 125 µin.) a soft faced hammer and a wooden block.

(0.25 in.) narrower than the total width of the After the sleeve is in the desired position,

sleeve. The flange adds a nominal 25,4 mm NOTE: The shaft tolerances for LDSLV check the lead-in chamfer for any damage

(1 in.) over the shaft diameter. The flange designs, due to their heated slip-fit installa- during installation.

height is 12,7 mm (0.5 in.) for all sizes. Note tion, are different from those for radial shaft

that force should never be applied directly to seals. Contact SKF for assistance if the sleeves

the flange when installing an LDSLV3. are to be used in systems with sustained tem- Removal

LDSLV4 has the same features as LDSLV3 peratures higher than 75 °C (165 °F) and sur- Wear sleeves for heavy industrial applications

but has no flange. LDSLV4 is intended for face speeds in excess of 20 m/s (3 900 ft/min). can be removed either by heating them or

applications where a flange could interfere expanding them by light hammer blows. Prior

with other components during installation, to removal, the flange of the LDSLV3 should

or where a wider contact surface for the seal first be cut through at one point, using care

is required. not to damage the shaft surface.

LDSLV3 LDSLV4 Using LDSLV designs

Fig. 1 Fig. 2 Fig. 3

Alternative 2

Original shaft

Alternative 1

33