Page 45 - Rollingbearings

P. 45

Tolerance values

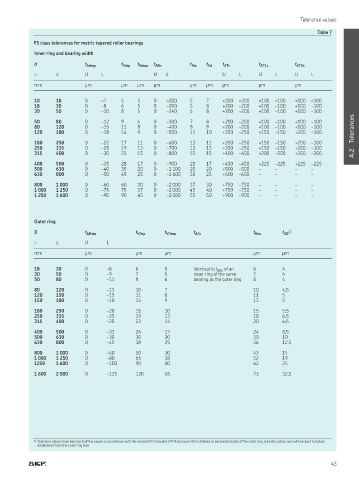

Table 7

P5 class tolerances for metric tapered roller bearings

Inner ring and bearing width

d t Δdmp t Vdsp t Vdmp t ΔBs t Kia t Sd t ΔTs t ΔT1s t ΔT2s

> ≤ U L U L U L U L U L

mm μm μm μm μm μm μm μm μm μm

10 18 0 –7 5 5 0 –200 5 7 +200 –200 +100 –100 +100 –100

18 30 0 –8 6 5 0 –200 5 8 +200 –200 +100 –100 +100 –100

30 50 0 –10 8 5 0 –240 6 8 +200 –200 +100 –100 +100 –100

50 80 0 –12 9 6 0 –300 7 8 +200 –200 +100 –100 +100 –100

80 120 0 –15 11 8 0 –400 8 9 +200 –200 +100 –100 +100 –100 Tolerances

120 180 0 –18 14 9 0 –500 11 10 +350 –250 +150 –150 +200 –100

180 250 0 –22 17 11 0 –600 13 11 +350 –250 +150 –150 +200 –100

250 315 0 –25 19 13 0 –700 13 13 +350 –250 +150 –150 +200 –100

315 400 0 –30 23 15 0 –800 15 15 +400 –400 +200 –200 +200 –200 A.2

400 500 0 –35 28 17 0 –900 20 17 +450 –450 +225 –225 +225 –225

500 630 0 –40 35 20 0 –1 100 25 20 +500 –500 – – – –

630 800 0 –50 45 25 0 –1 600 30 25 +600 –600 – – – –

800 1 000 0 –60 60 30 0 –2 000 37 30 +750 –750 – – – –

1 000 1 250 0 –75 75 37 0 –2 000 45 40 +750 –750 – – – –

1 250 1 600 0 –90 90 45 0 –2 000 55 50 +900 –900 – – – –

Outer ring

D t ΔDmp t VDsp t VDmp t ΔCs t Kea t SD 1)

> ≤ U L

mm μm μm μm μm μm

18 30 0 –8 6 5 Identical to t ∆Bs of an 6 4

30 50 0 –9 7 5 inner ring of the same 7 4

50 80 0 –11 8 6 bearing as the outer ring 8 4

80 120 0 –13 10 7 10 4,5

120 150 0 –15 11 8 11 5

150 180 0 –18 14 9 13 5

180 250 0 –20 15 10 15 5,5

250 315 0 –25 19 13 18 6,5

315 400 0 –28 22 14 20 6,5

400 500 0 –33 26 17 24 8,5

500 630 0 –38 30 20 30 10

630 800 0 –45 38 25 36 12,5

800 1 000 0 –60 50 30 43 15

1 000 1 250 0 –80 65 38 52 19

1250 1 600 0 –100 90 50 62 25

1 600 2 000 0 –125 120 65 73 32,5

1) Tolerance values have become half the values in accordance with the revised ISO standard (2014) because SD is deined as perpendicularity of the outer ring outside surface axis with respect to datum

established from the outer ring face.

43