Page 43 - Rollingbearings

P. 43

Tolerance values

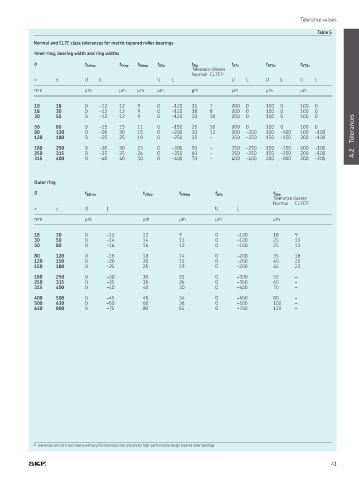

Table 5

Normal and CL7C class tolerances for metric tapered roller bearings

Inner ring, bearing width and ring widths

d t ∆dmp t Vdsp t Vdmp t ∆Bs t Kia t ∆Ts t ∆T1s t ∆T2s

Tolerance classes

Normal CL7C 1)

> ≤ U L U L U L U L U L

mm µm µm µm µm µm µm µm µm

10 18 0 –12 12 9 0 –120 15 7 200 0 100 0 100 0

18 30 0 –12 12 9 0 –120 18 8 200 0 100 0 100 0

30 50 0 –12 12 9 0 –120 20 10 200 0 100 0 100 0

50 80 0 –15 15 11 0 –150 25 10 200 0 100 0 100 0 Tolerances

80 120 0 –20 20 15 0 –200 30 13 200 –200 100 –100 100 –100

120 180 0 –25 25 19 0 –250 35 – 350 –250 150 –150 200 –100

180 250 0 –30 30 23 0 –300 50 – 350 –250 150 –150 200 –100

250 315 0 –35 35 26 0 –350 60 – 350 –250 150 –150 200 –100 A.2

315 400 0 –40 40 30 0 –400 70 – 400 –400 200 –200 200 –200

Outer ring

D t ∆Dmp t VDsp t VDmp t ∆Cs t Kea

Tolerance classes

Normal CL7C 1)

> ≤ U L U L

mm µm µm µm µm µm

18 30 0 –12 12 9 0 –120 18 9

30 50 0 –14 14 11 0 –120 20 10

50 80 0 –16 16 12 0 –150 25 13

80 120 0 –18 18 14 0 –200 35 18

120 150 0 –20 20 15 0 –250 40 20

150 180 0 –25 25 19 0 –250 45 23

180 250 0 –30 30 23 0 –300 50 –

250 315 0 –35 35 26 0 –350 60 –

315 400 0 –40 40 30 0 –400 70 –

400 500 0 –45 45 34 0 –450 80 –

500 630 0 –50 60 38 0 –500 100 –

630 800 0 –75 80 55 0 –750 120 –

1) Tolerances are not in accordance with any ISO tolerance class and are for high-performance design tapered roller bearings.

41