Page 42 - Rollingbearings

P. 42

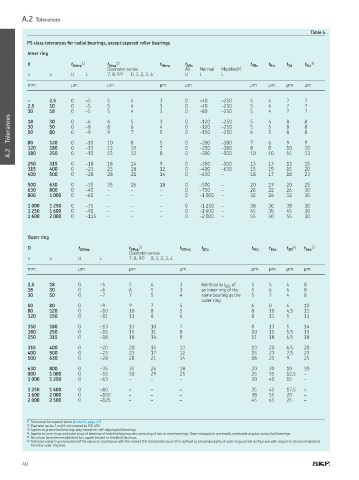

A.2 Tolerances

Table 4

P5 class tolerances for radial bearings, except tapered roller bearings

Inner ring

d t ∆dmp 1) t Vdsp 1) t Vdmp t ∆Bs t VBs t Kia t Sd t Sia 3)

Diameter series All Normal Modiied 4)

> ≤ U L 7, 8, 9 2) 0, 1, 2, 3, 4 U L L

mm µm µm µm µm µm µm µm µm

– 2,5 0 –5 5 4 3 0 –40 –250 5 4 7 7

2,5 10 0 –5 5 4 3 0 –40 –250 5 4 7 7

10 18 0 –5 5 4 3 0 –80 –250 5 4 7 7

Tolerances 18 30 0 0 0 –6 6 8 9 5 6 7 3 4 5 0 0 0 –120 –250 5 5 6 4 5 5 8 8 8 8 8 8

–8

–120

–250

30

50

80

–9

50

–150

–250

–380

180

–13

120

–250

13

A.2 80 120 0 0 0 –10 10 8 10 5 7 8 0 0 0 –200 –380 7 8 10 6 8 10 9 10 9 10

12

–300

–15

15

–500

180

11

250

13

250 315 0 –18 18 14 9 0 –350 –500 13 13 13 15

315 400 0 –23 23 18 12 0 –400 –630 15 15 15 20

400 500 0 –28 28 21 14 0 –450 – 18 17 18 23

500 630 0 –35 35 26 18 0 –500 – 20 19 20 25

630 800 0 –45 – – – 0 –750 – 26 22 26 30

800 1 000 0 –60 – – – 0 –1 000 – 32 26 32 30

1 000 1 250 0 –75 – – – 0 –1 250 – 38 30 38 30

1 250 1 600 0 –90 – – – 0 –1 600 – 45 35 45 30

1 600 2 000 0 –115 – – – 0 –2 000 – 55 40 55 30

Outer ring

D t ∆Dmp t VDsp 5) t VDmp t ∆Cs t VCs t Kea t SD 6) t Sea 3)

Diameter series

> ≤ U L 7, 8, 9 2) 0, 1, 2, 3, 4

mm µm µm µm µm µm µm µm

2,5 18 0 –5 5 4 3 Identical to t ∆Bs of 5 5 4 8

18 30 0 –6 6 5 3 an inner ring of the 5 6 4 8

30 50 0 –7 7 5 4 same bearing as the 5 7 4 8

outer ring

50 80 0 –9 9 7 5 6 8 4 10

80 120 0 –10 10 8 5 8 10 4,5 11

120 150 0 –11 11 8 6 8 11 5 13

150 180 0 –13 13 10 7 8 13 5 14

180 250 0 –15 15 11 8 10 15 5,5 15

250 315 0 –18 18 14 9 11 18 6,5 18

315 400 0 –20 20 15 10 13 20 6,5 20

400 500 0 –23 23 17 12 15 23 7,5 23

500 630 0 –28 28 21 14 18 25 9 25

630 800 0 –35 35 26 18 20 30 10 30

800 1 000 0 –50 50 29 25 25 35 12,5 –

1 000 1 250 0 –63 – – – 30 40 15 –

1 250 1 600 0 –80 – – – 35 45 17,5 –

1 600 2 000 0 –100 – – – 38 55 20 –

2 000 2 500 0 –125 – – – 45 65 25 –

1) Tolerances for tapered bores (table 11, page 47).

2) Diameter series 7 and 8 not covered by ISO 492.

3) Applies to groove ball bearings only, except for self-aligning ball bearings.

4) Applies to inner rings and outer rings of bearings of matched bearing sets consisting of two or more bearings. Does not apply to universally matchable angular contact ball bearings.

5) No values have been established for capped (sealed or shielded) bearings.

6) Tolerance values have become half the values in accordance with the revised ISO standard because SD is deined as perpendicularity of outer ring outside surface axis with respect to datum established

from the outer ring face.

40