Page 49 - Rollingbearings

P. 49

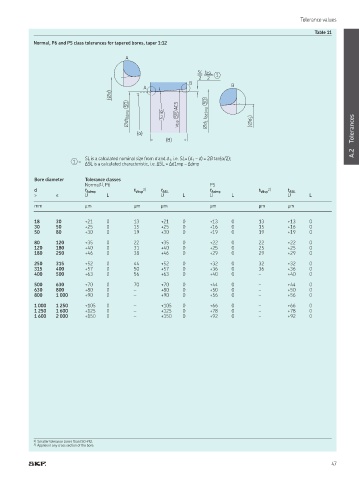

Tolerance values

Table 11

Normal, P6 and P5 class tolerances for tapered bores, taper 1:12

A

SL t ΔSL

1

2 2

B

A B

(∅d)

∅dt DΔmp SD α 2 Vdsp SR ACS ∅d 1 t Δd1mp SD (∅d 1 )

(α) Tolerances

(B)

A.2

SL is a calculated nominal size from d and d , i.e. SL= (d – d) = 2B tan(α/2);

1

1

1 =

∆SL is a calculated characteristic, i.e. ∆SL = ∆d1mp – ∆dmp

Bore diameter Tolerance classes

Normal 1) , P6 P5

d t ∆dmp t Vdsp 2) t ∆SL t ∆dmp t Vdsp 2) t ∆SL

> ≤ U L U L U L U L

mm µm µm µm µm µm µm

18 30 +21 0 13 +21 0 +13 0 13 +13 0

30 50 +25 0 15 +25 0 +16 0 15 +16 0

50 80 +30 0 19 +30 0 +19 0 19 +19 0

80 120 +35 0 22 +35 0 +22 0 22 +22 0

120 180 +40 0 31 +40 0 +25 0 25 +25 0

180 250 +46 0 38 +46 0 +29 0 29 +29 0

250 315 +52 0 44 +52 0 +32 0 32 +32 0

315 400 +57 0 50 +57 0 +36 0 36 +36 0

400 500 +63 0 56 +63 0 +40 0 – +40 0

500 630 +70 0 70 +70 0 +44 0 – +44 0

630 800 +80 0 – +80 0 +50 0 – +50 0

800 1 000 +90 0 – +90 0 +56 0 – +56 0

1 000 1 250 +105 0 – +105 0 +66 0 – +66 0

1 250 1 600 +125 0 – +125 0 +78 0 – +78 0

1 600 2 000 +150 0 – +150 0 +92 0 – +92 0

1) Smaller tolerance zones than ISO 492.

2) Applies in any cross section of the bore.

47