Page 52 - Rollingbearings

P. 52

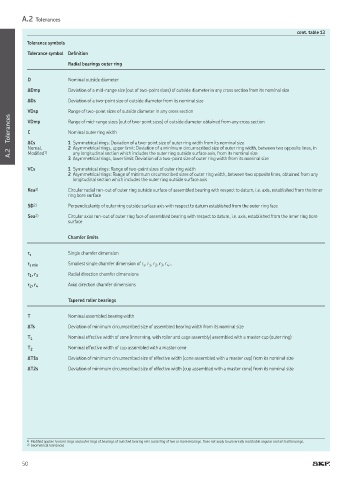

A.2 Tolerances

cont. table 13

Tolerance symbols

Tolerance symbol Deinition

Radial bearings outer ring

D Nominal outside diameter

ΔDmp Deviation of a mid-range size (out of two-point sizes) of outside diameter in any cross section from its nominal size

ΔDs Deviation of a two-point size of outside diameter from its nominal size

VDsp Range of two-point sizes of outside diameter in any cross section

Tolerances VDmp Range of mid-range sizes (out of two-point sizes) of outside diameter obtained from any cross section

Nominal outer ring width

C

Nomal,

2 Asymmetrical rings, upper limit: Deviation of a minimum circumscribed size of outer ring width, between two opposite lines, in

A.2 ΔCs 1 Symmetrical rings: Deviation of a two-point size of outer ring width from its nominal size

Modiied 1)

any longitudinal section which includes the outer ring outside surface axis, from its nominal size

3 Asymmetrical rings, lower limit: Deviation of a two-point size of outer ring width from its nominal size

VCs 1 Symmetrical rings: Range of two-point sizes of outer ring width

2 Asymmetrical rings: Range of minimum circumscribed sizes of outer ring width, between two opposite lines, obtained from any

longitudinal section which includes the outer ring outside surface axis

Kea 2) Circular radial run-out of outer ring outside surface of assembled bearing with respect to datum, i.e. axis, established from the inner

ring bore surface

SD 2) Perpendicularity of outer ring outside surface axis with respect to datum established from the outer ring face

Sea 2) Circular axial run-out of outer ring face of assembled bearing with respect to datum, i.e. axis, established from the inner ring bore

surface

Chamfer limits

r s Single chamfer dimension

Smallest single chamfer dimension of r , r , r , r , r …

r s min s 1 2 3 4

Radial direction chamfer dimensions

r 1 , r 3

r 2 , r 4 Axial direction chamfer dimensions

Tapered roller bearings

T Nominal assembled bearing width

ΔTs Deviation of minimum circumscribed size of assembled bearing width from its nominal size

T 1 Nominal effective width of cone (inner ring, with roller and cage assembly) assembled with a master cup (outer ring)

Nominal effective width of cup assembled with a master cone

T 2

ΔT1s Deviation of minimum circumscribed size of effective width (cone assembled with a master cup) from its nominal size

ΔT2s Deviation of minimum circumscribed size of effective width (cup assembled with a master cone) from its nominal size

1) Modiied applies to inner rings and outer rings of bearings of matched bearing sets consisting of two or more bearings. Does not apply to universally matchable angular contact ball bearings.

2) Geometrical tolerances

50