Page 5 - SKF-SPEEDI-SLEEVE

P. 5

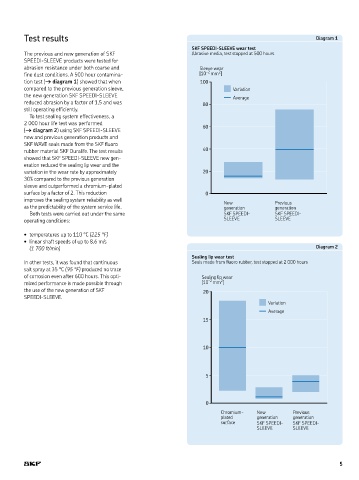

Test results Diagram 1

SKF SPEEDI-SLEEVE wear test

The previous and new generation of SKF Abrasive media, test stopped at 500 hours

SPEEDI-SLEEVE products were tested for

abrasion resistance under both coarse and Sleeve wear

2

-2

fine dust conditions. A 500 hour contamina- [10 mm ]

tion test († diagram 1) showed that when 100

compared to the previous generation sleeve, Variation

the new generation SKF SPEEDI-SLEEVE Average

reduced abrasion by a factor of 1,5 and was 80

still operating efficiently.

To test sealing system effectiveness, a

2 000 hour life test was performed 60

(† diagram 2) using SKF SPEEDI-SLEEVE

new and previous generation products and

SKF WAVE seals made from the SKF fluoro

rubber material SKF Duralife. The test results 40

showed that SKF SPEEDI-SLEEVE new gen-

eration reduced the sealing lip wear and the

variation in the wear rate by approximately 20

30% compared to the previous generation

sleeve and outperformed a chromium-plated

surface by a factor of 2. This reduction 0

improves the sealing system reliability as well New Previous

as the predictability of the system service life. generation generation

Both tests were carried out under the same SKF SPEEDI- SKF SPEEDI-

operating conditions: SLEEVE SLEEVE

• temperatures up to 110 °C (225 °F)

• linear shaft speeds of up to 8,6 m/s

(1 700 ft/min) Diagram 2

Sealing lip wear test

In other tests, it was found that continuous Seals made from fluoro rubber, test stopped at 2 000 hours

salt spray at 35 °C (95 °F) produced no trace

of corrosion even after 600 hours. This opti- Sealing lip wear

2

-2

mized performance is made possible through [10 mm ]

the use of the new generation of SKF 20

SPEEDI-SLEEVE.

Variation

Average

15

10

5

0

Chromium- New Previous

plated generation generation

surface SKF SPEEDI- SKF SPEEDI-

SLEEVE SLEEVE

5