Page 406 - Rollingbearings

P. 406

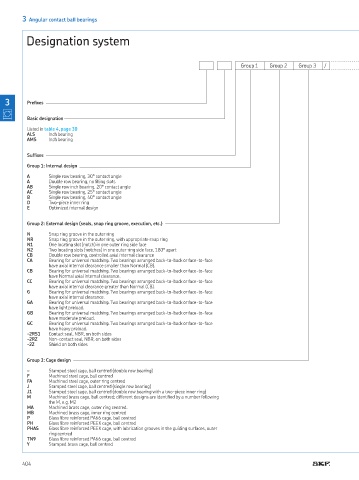

Designation system

3 Angular contact ball bearings

Designation system

Group 1 Group 2 Group 3 /

3 Preixes

Basic designation

Listed in table 4, page 30

ALS Inch bearing

AMS Inch bearing

Sufixes

Group 1: Internal design

A Single row bearing, 30° contact angle

A Double row bearing, no illing slots

AB Single row inch bearing, 20° contact angle

AC Single row bearing, 25° contact angle

B Single row bearing, 40° contact angle

D Two-piece inner ring

E Optimized internal design

Group 2: External design (seals, snap ring groove, execution, etc.)

N Snap ring groove in the outer ring

NR Snap ring groove in the outer ring, with appropriate snap ring

N1 One locating slot (notch) in one outer ring side face

N2 Two locating slots (notches) in one outer ring side face, 180° apart

CB Double row bearing, controlled axial internal clearance

CA Bearing for universal matching Two bearings arranged back-to-back or face-to-face

have axial internal clearance smaller than Normal (CB)

CB Bearing for universal matching Two bearings arranged back-to-back or face-to-face

have Normal axial internal clearance

CC Bearing for universal matching Two bearings arranged back-to-back or face-to-face

have axial internal clearance greater than Normal (CB)

G Bearing for universal matching Two bearings arranged back-to-back or face-to-face

have axial internal clearance

GA Bearing for universal matching Two bearings arranged back-to-back or face-to-face

have light preload

GB Bearing for universal matching Two bearings arranged back-to-back or face-to-face

have moderate preload

GC Bearing for universal matching Two bearings arranged back-to-back or face-to-face

have heavy preload

-2RS1 Contact seal, NBR, on both sides

-2RZ Non-contact seal, NBR, on both sides

-2Z Shield on both sides

Group 3: Cage design

– Stamped steel cage, ball centred (double row bearing)

F Machined steel cage, ball centred

FA Machined steel cage, outer ring centred

J Stamped steel cage, ball centred (single row bearing)

J1 Stamped steel cage, ball centred (double row bearing with a two-piece inner ring)

M Machined brass cage, ball centred; different designs are identiied by a number following

the M, e g M2

MA Machined brass cage, outer ring centred

MB Machined brass cage, inner ring centred

P Glass ibre reinforced PA66 cage, ball centred

PH Glass ibre reinforced PEEK cage, ball centred

PHAS Glass ibre reinforced PEEK cage, with lubrication grooves in the guiding surfaces, outer

ring centred

TN9 Glass ibre reinforced PA66 cage, ball centred

Y Stamped brass cage, ball centred

404