Page 206 - Rollingbearings

P. 206

B.8 Sealing, mounting and dismounting

Mounting with SKF hydraulic nuts Oil injection method Verifying the interference it

Bearings with a tapered bore can be With the oil injection method, oil under high During mounting, the degree of interference

mounted with the aid of an SKF hydraulic pressure is injected via ducts and distribu- is normally determined by one of the follow-

nut: tion grooves between the bearing and bear- ing methods:

ing seat to form an oil ilm This oil ilm sep-

• on a tapered shaft seat (ig. 32) arates the mating surfaces and considerably • measuring the clearance reduction

• on an adapter sleeve (ig. 33) reduces the friction between them This • measuring the lock nut tightening angle

• on a withdrawal sleeve (ig. 34) method is typically used when mounting • measuring the axial drive-up

bearings directly on tapered shaft seats • measuring the inner ring expansion

The hydraulic nut can be positioned onto a (ig. 35) The necessary ducts and grooves

threaded section of the shaft (ig. 32), or should be an integral part of the shaft For self-aligning ball bearings, feeling the

onto the thread of a sleeve (ig. 33 and design This method can also be used to clearance reduction by swivelling the outer

ig. 34) The annular piston abuts the inner mount bearings on adapter or withdrawal ring is an additional method (Mounting,

ring of the bearing (ig. 32 and ig. 33) or a sleeves if they are equipped with the relevant page 447)

stop on the shaft, which can be either a nut features, ducts and grooves

on a shaft thread (ig. 34) or a plate attached A spherical roller bearing mounted on a

to the end of the shaft Pumping oil into the withdrawal sleeve with oil ducts is shown in

hydraulic nut displaces the piston axially with ig. 36 Oil is injected between all mating

the force needed to drive the inner ring up surfaces so that the withdrawal sleeve can

the taper for accurate and safe mounting be pressed into the bearing bore as the bolts

are tightened

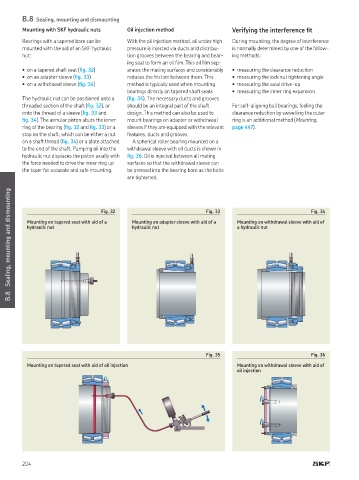

Sealing, mounting and dismounting Mounting on tapered seat with aid of a Mounting on adapter sleeve with aid of a Mounting on withdrawal sleeve with aid of

Fig. 33

Fig. 32

Fig. 34

hydraulic nut

hydraulic nut

a hydraulic nut

B.8

Fig. 35 Fig. 36

Mounting on tapered seat with aid of oil injection Mounting on withdrawal sleeve with aid of

oil injection

204