Page 203 - Rollingbearings

P. 203

Mounting and dismounting

Methods and tools Mounting bearings with a Cold mounting

Depending on the bearing type and size, cylindrical bore If the it is not too tight, small bearings can

mechanical, thermal or hydraulic methods be driven into position by applying light

are used for mounting (table 2, page 202) Non-separable bearings hammer blows to a bearing itting tool

Bearing sizes are categorized as follows: (ig. 28) The tool enables the mounting

With non-separable bearings, the ring that force to be applied centrally

• small → d ≤ 80 mm requires the tighter it is usually mounted If a bearing has to be pressed onto the

• medium-size → 80 mm < d < 200 mm irst shaft and into the housing bore at the same

• large → d ≥ 200 mm time, the mounting force must be applied

Separable bearings equally to both rings and the abutment sur-

In all cases, it is important that the bearing faces of the mounting tool must lie in the

rings, cages and rolling elements or seals With separable bearings, the inner ring can same plane Whenever possible, mounting

are never struck directly with any hard object be mounted independently of the outer ring, should be done with an SKF bearing itting

and that the mounting force is never applied which simpliies mounting, particularly tool (ig. 28)

through the rolling elements where both rings have an interference it With self-aligning bearings, the use of an

For an interference it, the mating sur- When mounting the shaft and inner ring intermediate mounting ring prevents the

faces should be coated with a thin layer of assembly into the housing containing the outer ring from tilting and swivelling when

light oil For a loose it, the mating surfaces outer ring, careful alignment is required to the bearing and shaft assembly is introduced

should be coated with SKF anti-fretting avoid scoring the raceways and rolling ele- into the housing bore (ig. 29) The balls of

agent ments When mounting cylindrical or needle larger self-aligning ball bearings in the 12

roller bearings with an inner ring without and 13 series protrude from the sides of the

langes or with a lange on one side only, a bearing, therefore the mounting ring must

Sealing, mounting and dismounting

guiding sleeve should be used (ig. 27) The have a recess

outside diameter of the sleeve should be the

same as the raceway diameter of the inner

ring and should be machined to tolerance

class d10� for cylindrical roller bearings,

and to tolerance 0/–0,025 mm for needle

roller bearings

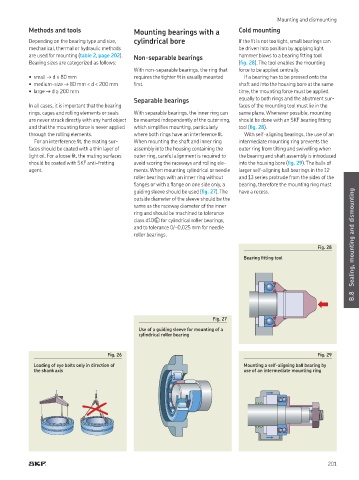

Fig. 28

Bearing itting tool

B.8

Fig. 27

Use of a guiding sleeve for mounting of a

cylindrical roller bearing

Fig. 26 Fig. 29

Loading of eye bolts only in direction of Mounting a self-aligning ball bearing by

the shank axis use of an intermediate mounting ring

201