Page 198 - Rollingbearings

P. 198

B.8 Sealing, mounting and dismounting

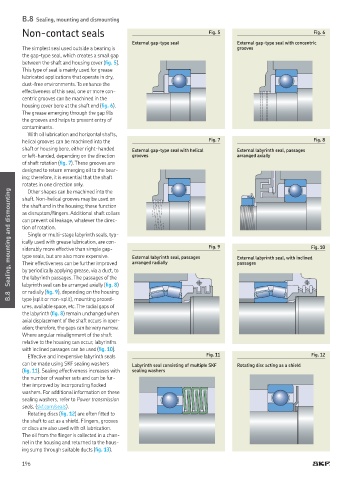

Non-contact seals Fig. 5 Fig. 6

External gap-type seal External gap-type seal with concentric

The simplest seal used outside a bearing is grooves

the gap-type seal, which creates a small gap

between the shaft and housing cover (ig. 5)

This type of seal is mainly used for grease

lubricated applications that operate in dry,

dust-free environments To enhance the

effectiveness of this seal, one or more con-

centric grooves can be machined in the

housing cover bore at the shaft end (ig. 6)

The grease emerging through the gap ills

the grooves and helps to prevent entry of

contaminants

With oil lubrication and horizontal shafts,

helical grooves can be machined into the Fig. 7 Fig. 8

shaft or housing bore, either right-handed External gap-type seal with helical External labyrinth seal, passages

or left-handed, depending on the direction grooves arranged axially

of shaft rotation (ig. 7) These grooves are

designed to return emerging oil to the bear-

ing; therefore, it is essential that the shaft

rotates in one direction only

Sealing, mounting and dismounting as disruptors/lingers Additional shaft collars External labyrinth seal, passages Fig. 9 External labyrinth seal, with inclined Fig. 10

Other shapes can be machined into the

shaft Non-helical grooves may be used on

the shaft and in the housing; these function

can prevent oil leakage, whatever the direc-

tion of rotation

Single or multi-stage labyrinth seals, typ-

ically used with grease lubrication, are con-

siderably more effective than simple gap-

type seals, but are also more expensive

arranged radially

Their effectiveness can be further improved

passages

the labyrinth passages The passages of the

labyrinth seal can be arranged axially (ig. 8)

B.8 by periodically applying grease, via a duct, to

or radially (ig. 9), depending on the housing

type (split or non-split), mounting proced-

ures, available space, etc The radial gaps of

the labyrinth (ig. 8) remain unchanged when

axial displacement of the shaft occurs in oper-

ation; therefore, the gaps can be very narrow

Where angular misalignment of the shaft

relative to the housing can occur, labyrinths

with inclined passages can be used (ig. 10)

Effective and inexpensive labyrinth seals Fig. 11 Fig. 12

can be made using SKF sealing washers Labyrinth seal consisting of multiple SKF Rotating disc acting as a shield

(ig. 11) Sealing effectiveness increases with sealing washers

the number of washer sets and can be fur-

ther improved by incorporating locked

washers For additional information on these

sealing washers, refer to Power transmission

seals, (skf com/seals)

Rotating discs (ig. 12) are often itted to

the shaft to act as a shield Flingers, grooves

or discs are also used with oil lubrication

The oil from the linger is collected in a chan-

nel in the housing and returned to the hous-

ing sump through suitable ducts (ig. 13)

196