Page 197 - Rollingbearings

P. 197

External sealing

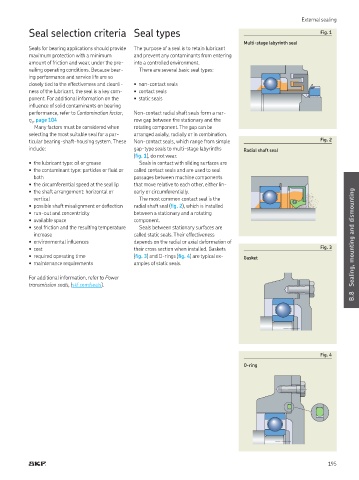

Seal selection criteria Seal types Fig. 1

Multi-stage labyrinth seal

Seals for bearing applications should provide The purpose of a seal is to retain lubricant

maximum protection with a minimum and prevent any contaminants from entering

amount of friction and wear, under the pre- into a controlled environment

vailing operating conditions Because bear- There are several basic seal types:

ing performance and service life are so

closely tied to the effectiveness and cleanli- • non-contact seals

ness of the lubricant, the seal is a key com- • contact seals

ponent For additional information on the • static seals

inluence of solid contaminants on bearing

performance, refer to Contamination factor, Non-contact radial shaft seals form a nar-

η , page 104 row gap between the stationary and the

c

Many factors must be considered when rotating component The gap can be

selecting the most suitable seal for a par- arranged axially, radially or in combination

ticular bearing-shaft-housing system These Non-contact seals, which range from simple Fig. 2

include: gap-type seals to multi-stage labyrinths Radial shaft seal

(ig. 1), do not wear

• the lubricant type: oil or grease Seals in contact with sliding surfaces are

• the contaminant type: particles or luid or called contact seals and are used to seal

both passages between machine components

• the circumferential speed at the seal lip that move relative to each other, either lin-

• the shaft arrangement: horizontal or early or circumferentially

vertical The most common contact seal is the

• possible shaft misalignment or delection radial shaft seal (ig. 2), which is installed

• run-out and concentricity between a stationary and a rotating

• available space component

• seal friction and the resulting temperature Seals between stationary surfaces are

increase called static seals Their effectiveness Sealing, mounting and dismounting

• environmental inluences depends on the radial or axial deformation of

• cost their cross section when installed Gaskets Fig. 3

• required operating time (ig. 3) and O-rings (ig. 4) are typical ex- Gasket

• maintenance requirements amples of static seals

For additional information, refer to Power

transmission seals, (skf com/seals)

B.8

Fig. 4

O-ring

195