Page 192 - Rollingbearings

P. 192

B.7 Bearing execution

Features for special

requirements

SKF supplies many more bearing variants, in

addition to those presented in the product

sections, for accomplishing various tasks and

satisfying special application needs Among

the more common special variants manu-

factured by SKF are:

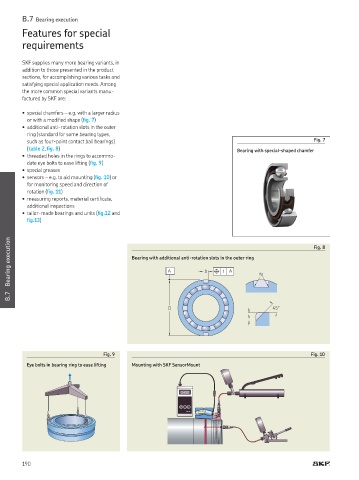

• special chamfers – e g with a larger radius

or with a modiied shape (ig. 7)

• additional anti-rotation slots in the outer

ring (standard for some bearing types,

such as four-point contact ball bearings) Fig. 7

(table 2, ig. 8) Bearing with special-shaped chamfer

• threaded holes in the rings to accommo-

date eye bolts to ease lifting (ig. 9)

• special greases

• sensors – e g to aid mounting (ig. 10) or

for monitoring speed and direction of

rotation (ig. 11)

• measuring reports, material certiicate,

additional inspections

• tailor-made bearings and units (ig.12 and

ig.13)

Bearing execution Bearing with additional anti-rotation slots in the outer ring r 0 Fig. 8

b

A

A

t

B.7

D 45 °

h

Fig. 9 Fig. 10

Eye bolts in bearing ring to ease lifting Mounting with SKF SensorMount

0.450

ON CLR MAX

0FF

TMEM 1500

190