Page 190 - Rollingbearings

P. 190

B.7 Bearing execution

Steel cages dependent and subject to ageing The factors Polyamide 46

that most inluence the ageing process are Glass ibre reinforced polyamide 46 (PA46) is

Steel cages can be used at operating tem- temperature, time and the medium (lubri- the standard cage material for some small

peratures up to 300 °C (570 °F) cant) to which the polymer is exposed The and medium- size CARB toroidal roller bear-

relationship between these factors for glass ings The permissible operating temperature

Sheet steel cages ibre reinforced PA66 is shown in diagram 5 is 15 °C (25 °F) higher than for glass ibre

Cage life decreases with increasing tempera- reinforced PA66

Stamped sheet steel cages are made of low ture and the aggressiveness of the lubricant

carbon steel These lightweight cages have Therefore, whether polyamide cages are Polyetheretherketone

relatively high strength and, for some bear- suitable for a speciic application depends on

ing types, can be surface treated to further the operating conditions and life require- Glass ibre reinforced polyetheretherketone

reduce friction and wear in critical ments The classiication of lubricants into (PEEK) is more suitable for demanding con-

conditions “aggressive” and “mild” is relected by the ditions regarding high speeds, chemical

“permissible operating temperature” for resistance or high temperatures than PA66

Machined steel cages cages made of glass ibre reinforced PA66 and PA46 The exceptional properties of

with various lubricants (table 1) The per- PEEK provide a superior combination of

Machined steel cages are normally made of missible operating temperature in table 1 is strength and lexibility, high operating tem-

non-alloyed structural steel To reduce fric- deined as the temperature that provides a perature range, and high chemical and wear

tion and wear, some machined steel cages cage ageing life of at least 10 000 operating resistance Because of these outstanding

are surface treated hours features, PEEK cages are commonly availa-

Machined steel cages are not affected by Some media are even more “aggressive” ble for hybrid and/or super- precision ball

the mineral or synthetic oil-based lubricants than those speciied in table 1 A typical and cylindrical roller bearings The material

normally used for rolling bearings, or by the ex ample is ammonia, used as a refrigerant does not show signs of ageing by tempera-

organic solvents used to clean bearings in compressors In those cases, cages made ture or oil additives up to 200 °C (390 °F)

of glass ibre reinforced PA66 should not be However, the maximum temperature for

used at operating temperatures above high -speed use is limited to 150 °C

Brass cages 70 °C (160 °F) (300 °F) as this is the softening temperature

Polyamide loses its elasticity at low tem- of the polymer

Brass cages can be used at operating tem- peratures Therefore, cages made of glass

Bearing execution Sheet brass cages applications where the continuous operating

peratures up to 250 °C (480 °F)

ibre reinforced PA66 should not be used in

temperature is below –40 °C (–40 °F)

Stamped sheet brass cages are used for

some small and medium -size bearings In

sors that use ammonia, machined brass or

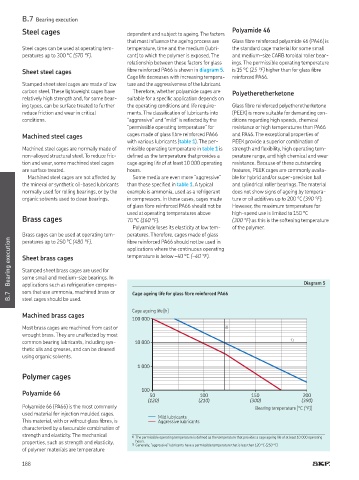

B.7 applications such as refrigeration compres- Cage ageing life for glass ibre reinforced PA66 Diagram 5

steel cages should be used

Cage ageing life [h]

Machined brass cages

100 000

Most brass cages are machined from cast or 2)

wrought brass They are unaffected by most

common bearing lubricants, including syn- 10 000 1)

thetic oils and greases, and can be cleaned

using organic solvents

1 000

Polymer cages

100

Polyamide 66 50 100 150 200

(120) (210) (300) (390)

Polyamide 66 (PA66) is the most commonly Bearing temperature [°C (°F)]

used material for injection moulded cages

Mild lubricants

This material, with or without glass ibres, is Aggressive lubricants

characterized by a favourable combination of

strength and elasticity The mechanical 1) The permissible operating temperature is deined as the temperature that provides a cage ageing life of at least 10 000 operating

properties, such as strength and elasticity, 2) Generally, “aggressive” lubricants have a permissible temperature that is less than 120 °C (250 °F)

hours

of polymer materials are temperature

188