Page 189 - Rollingbearings

P. 189

Cages

Cages

For small electric motors, values of between Cages are mechanically stressed during

0,005 and 0,01 are used for the factor k. If bearing operation by frictional, impact, cen-

preload is used primarily to protect the bear- trifugal and inertial forces. They can also be

ing from the damage caused by external The main cage types are described in Com- chemically inluenced by certain organic solv-

vibrations when stationary, then greater ponents and materials, page 24. Additionally, ents or coolants, lubricants, and lubricant

preload is required and k = 0,02 should be information about standard cages, and pos- additives. Therefore, the material type used

used. sible cage options, for a particular bearing for a cage has a signiicant inluence on the

Spring loading is also a common method type is given in the relevant product section. suitability of a rolling bearing for a particular

of applying preload to angular contact ball If a bearing with a non -standard cage is application.

bearings in high-speed grinding spindles. required, check availability before ordering.

The method is not suitable for bearing appli- There are fundamental design differences

cations where a high degree of stiffness is between bearings which, together with the

required, where the direction of axial load inluence of bearing size, make certain cage

changes, or where undeined peak loads can designs necessary. For example:

occur.

For additional information, refer to • some bearing types need either split or

Bearing preload, (skf.com/go/17000-B7). snap-type cages, because they are

assembled after the rings and rolling ele-

ments have been sub-assembled

• other bearing types need roller-guided

Bearing tolerance • bearings of a certain combination of size

cages, to be self-containing

class and series need ring-guided cages, to limit

contact stress between rolling elements

and cage

The dimensional and geometrical tolerances

of bearings are described by their tolerance Given the speciic functional demands and

classes (Tolerances, page 36). In addition to quantity of bearings being manufactured,

the Normal, P6 and P5 tolerance classes, the material and manufacturing methods

SKF also manufactures bearings with even are chosen to provide the most reliable and

narrower tolerances. These include P4, UP cost-effective cage.

and other tolerance classes. For information

about SKF bearings that have a tolerance Bearing execution

class better than P5, refer to

skf.com/super-precision.

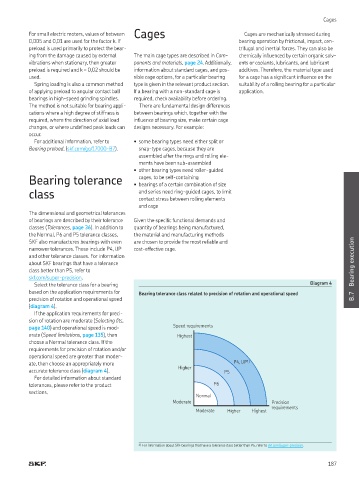

Select the tolerance class for a bearing Diagram 4

based on the application requirements for Bearing tolerance class related to precision of rotation and operational speed

precision of rotation and operational speed B.7

(diagram 4).

If the application requirements for preci-

sion of rotation are moderate (Selecting its,

page 140) and operational speed is mod- Speed requirements

erate (Speed limitations, page 135), then Highest

choose a Normal tolerance class. If the

requirements for precision of rotation and/or

operational speed are greater than moder-

ate, then choose an appropriately more P4, UP 1)

Higher

accurate tolerance class (diagram 4). P5

For detailed information about standard

tolerances, please refer to the product P6

sections.

Normal

Moderate Precision

requirements

Moderate Higher Highest

1) For information about SKF bearings that have a tolerance class better than P5, refer to skf.com/super-precision.

187