Page 209 - Rollingbearings

P. 209

Mounting and dismounting

During the test run, or immediately after- Dismounting bearings itted

wards, check the seals, any lubrication sys- on a cylindrical shaft seat

tems and all luid levels If noise and vibra-

tion levels are severe, it is advisable to check Cold dismounting

the lubricant for signs of contamination

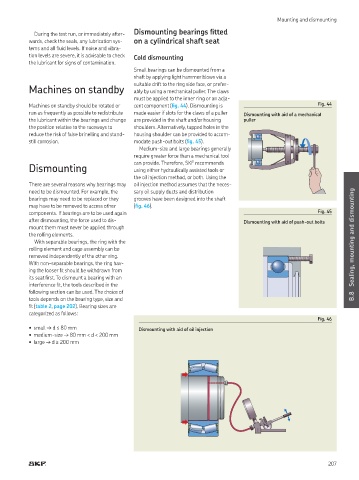

Small bearings can be dismounted from a

shaft by applying light hammer blows via a

suitable drift to the ring side face, or prefer-

Machines on standby ably by using a mechanical puller The claws

must be applied to the inner ring or an adja-

Machines on standby should be rotated or cent component (ig. 44) Dismounting is Fig. 44

run as frequently as possible to redistribute made easier if slots for the claws of a puller Dismounting with aid of a mechanical

the lubricant within the bearings and change are provided in the shaft and/or housing puller

the position relative to the raceways to shoulders Alternatively, tapped holes in the

reduce the risk of false brinelling and stand- housing shoulder can be provided to accom-

still corrosion modate push-out bolts (ig. 45)

Medium-size and large bearings generally

require greater force than a mechanical tool

can provide Therefore, SKF recommends

Dismounting using either hydraulically assisted tools or

the oil injection method, or both Using the

There are several reasons why bearings may oil injection method assumes that the neces-

need to be dismounted For example, the sary oil supply ducts and distribution

bearings may need to be replaced or they grooves have been designed into the shaft

may have to be removed to access other (ig. 46)

components If bearings are to be used again Fig. 45

after dismounting, the force used to dis- Dismounting with aid of push-out bolts

mount them must never be applied through

the rolling elements Sealing, mounting and dismounting

With separable bearings, the ring with the

rolling element and cage assembly can be

removed independently of the other ring

With non-separable bearings, the ring hav-

ing the looser it should be withdrawn from

its seat irst To dismount a bearing with an

interference it, the tools described in the

following section can be used The choice of

tools depends on the bearing type, size and B.8

it (table 2, page 202) Bearing sizes are

categorized as follows:

Fig. 46

• small → d ≤ 80 mm Dismounting with aid of oil injection

• medium-size → 80 mm < d < 200 mm

• large → d ≥ 200 mm

207