Page 123 - Rollingbearings

P. 123

Selecting a suitable oil

Additives Oil change interval Oil change intervals for mineral oils are

shown in table 10, page 122.

Lubricating oils usually contain additives of The oil change interval depends on the

various kinds. The most important ones are operating conditions and the oil type. With

antioxidants, corrosion protection agents, oil-bath lubrication, it is generally suficient

anti-foaming additives, and EP/AW addi- to change the oil once a year, provided the

tives. In the lubrication condition domain operating temperature does not exceed

deined by κ < 1, EP/AW additives are recom- 50 °C (120 °F). Typically, at higher tempera-

mended, but for temperatures above 80 °C tures or with heavy contamination, the oil

(175 °F), a lubricant with EP/AW additives must be changed more often.

should only be used after careful testing. With oil circulation, the interval after

which the oil needs to be changed is deter-

mined by an inspection of the oil quality,

taking into account oxidation and the pres-

ence of water and abrasive particles. Oil life

in circulation systems can be extended by

removing particles and water from the oil.

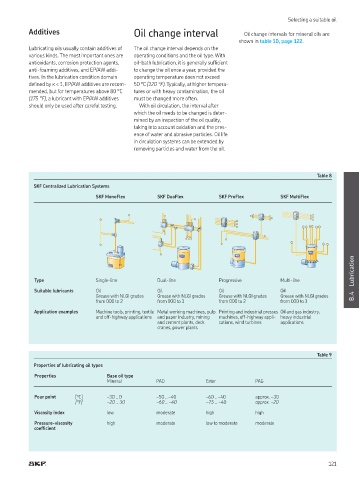

Table 8

SKF Centralized Lubrication Systems

SKF MonoFlex SKF DuoFlex SKF ProFlex SKF MultiFlex

Lubrication

Type Single-line Dual-line Progressive Multi-line

Suitable lubricants Oil Oil Oil Oil

Grease with NLGI grades Grease with NLGI grades Grease with NLGI grades Grease with NLGI grades B.4

from 000 to 2 from 000 to 3 from 000 to 2 from 000 to 3

Application examples Machine tools, printing, textile Metal working machines, pulp Printing and industrial presses Oil and gas industry,

and off-highway applications and paper industry, mining machines, off-highway appli- heavy industrial

and cement plants, deck cations, wind turbines applications

cranes, power plants

Table 9

Properties of lubricating oil types

Properties Base oil type

Mineral PAO Ester PAG

Pour point [°C] –30 0 –50 –40 –60 –40 approx –30

[°F] –20 .. 30 –60 .. –40 –75 .. –40 approx. –20

Viscosity index low moderate high high

Pressure-viscosity high moderate low to moderate moderate

coeficient

121