Page 128 - Rollingbearings

P. 128

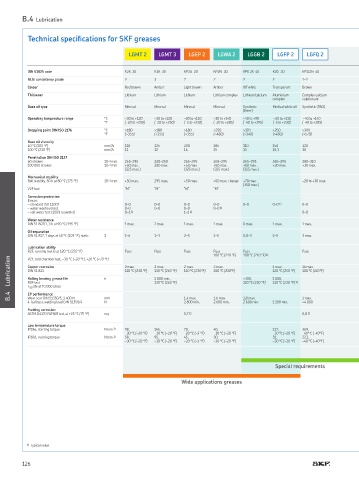

Technical speciications for SKF greases

B.4 Lubrication

Technical speciications for SKF greases

LGMT 2 LGMT 3 LGEP 2 LGWA 2 LGGB 2 LGFP 2 LGFQ 2

DIN 51825 code K2K-30 K3K-30 KP2G-20 KP2N-30 KPE 2K-40 K2G-20 KP1/2N-40

NLGI consistency grade 2 3 2 2 2 2 1–2

Colour Red brown Amber Light brown Amber Off white Transparent Brown

Thickener Lithium Lithium Lithium Lithium complex Lithium/calcium Aluminium Complex calcium

complex sulphonate

Base oil type Mineral Mineral Mineral Mineral Synthetic Medical white oil Synthetic (PAO)

(Ester)

Operating temperature range °C –30 to +120 –30 to +120 –20 to +110 –30 to +140 –40 to +90 –20 to +110 –40 to +140

°F (–20 to +250) (–20 to +250) (–5 to +230) (–20 to +285) (–40 to +195) (–5 to +230) (–40 to +285)

Dropping point DIN ISO 2176 °C >180 >180 >180 >250 >170 >250 >300

°F (>355) (>355) (>355) (>480) (>340) (>480) (>570)

Base oil viscosity

40 °C (105 °F) mm 2 /s 110 125 200 185 110 150 320

100 °C (210 °F) mm 2 /s 11 12 16 15 13 15,3 30

Penetration DIN ISO 2137

60 strokes 10 –1 mm 265–295 220–250 265–295 265–295 265–295 265–295 280–310

100 000 strokes 10 –1 mm +50 max. 280 max. +50 max. +50 max. +50 max. +30 max. +30 max.

(325 max.) (325 max.) (325 max.) (325 max.)

Mechanical stability

Roll stability, 50 h at 80 °C (175 °F) 10 –1 mm +50 max. 295 max. +50 max. +50 max. change +70 max. –20 to +30 max.

(350 max.)

V2F test “M” “M” “M” “M”

Corrosion protection

Emcor:

– standard ISO 11007 0–0 0–0 0–0 0–0 0–0 0–0 1) 0–0

– water washout test 0–0 0–0 0–0 0–0 1)

– salt water test (100% seawater) 0–1 1) 1–1 1) 0–0

Water resistance

DIN 51 807/1, 3 h at 90 °C (195 °F) 1 max. 2 max. 1 max. 1 max. 0 max. 1 max. 1 max.

Oil separation

DIN 51 817, 7 days at 40 °C (105 °F), static % 1–6 1–3 2–5 1–5 0,8–3 1–5 3 max.

Lubrication ability

R2F, running test B at 120 °C (250 °F) Pass Pass Pass Pass Pass Pass

100 °C (210 °F) 100 °C (210 °F) 1)

Lubrication Copper corrosion h 2 max. 2 max. 2 max. 2 max. >300, 1 max. 1b max.

R2F, cold chamber test, –30 °C (–20 °F), +20 °C (+70 °F)

100 °C (210°F)

110 °C (230 °F)

100 °C (210°F)

120 °C (250 °F)

130 °C (265 °F)

110 °C (230°F)

DIN 51 811

1 000,

1 000 min.,

Rolling bearing grease life

130 °C (265 °F)

120 °C (250 °F)

R0F test

110 °C (230 °F) 1)

B.4 L 50 life at 10 000 r/min mm 1,4 max. 1,6 max. 1,8 max. 1 max.

EP performance

Wear scar DIN 51350/5, 1 400 N

4–ball test, welding load DIN 51350/4 N 2 800 min. 2 600 min. 2 600 min. 1 100 min. >4 000

Fretting corrosion

ASTM D4170 FAFNIR test at +25 °C (75 °F) mg 5,7 1) 0,8 1)

Low temperature torque

IP186, starting torque Nmm 1) 98, 145, 70, 40, 137, 369,

–30 °C (–20 °F) –30 °C (–20 °F) –20 °C (–5 °F) –30 °C (–20 °F) –30 °C (–20 °F) –40° C (–40°F)

IP186, running torque Nmm 1) 58, 95, 45, 30, 51, 223,

–30 °C (–20 °F) –30 °C (–20 °F) –20 °C (–5 °F) –30 °C (–20 °F) –30 °C (–20 °F) –40 °C (–40°F)

Special requirements

Wide applications greases

1) Typical value

126