Page 126 - Rollingbearings

P. 126

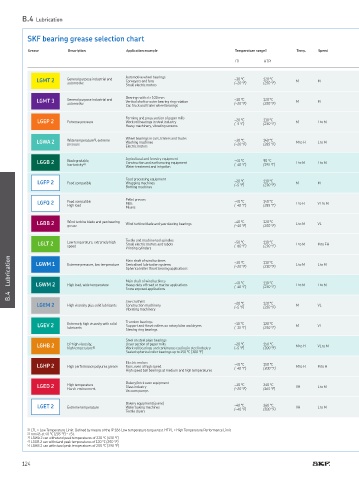

B.4 Lubrication

SKF bearing grease selection chart

Grease Description Application example Temperature range 1) Temp. Speed

LTL HTPL

Automotive wheel bearings

LGMT 2 General purpose industrial and Conveyors and fans –30 °C 120 °C M M

automotive (–20 °F) (250 °F)

Small electric motors

Bearings with d > 100 mm

LGMT 3 General purpose industrial and Vertical shaft or outer bearing ring rotation –30 °C 120 °C M M

automotive (–20 °F) (250 °F)

Car, truck and trailer wheel bearings

Forming and press section of paper mills

LGEP 2 Extreme pressure Work roll bearings in steel industry –20 °C 110 °C M L to M

Heavy machinery, vibrating screens (–5 °F) (230 °F)

Wheel bearings in cars, trailers and trucks

LGWA 2 Wide temperature 3) , extreme Washing machines –30 °C 140 °C M to H L to M

pressure (–20 °F) (285 °F)

Electric motors

Agricultural and forestry equipment

LGGB 2 Biodegradable, Construction and earthmoving equipment –40 °C 90 °C L to M L to M

low toxicity 4) (–40 °F) (195 °F)

Water treatment and irrigation

Food processing equipment

LGFP 2 Food compatible Wrapping machines –20 °C 110 °C M M

Bottling machines (–5 °F) (230 °F)

Pellet presses

LGFQ 2 Food compatible Mills –40 °C 140 °C L to H VL to M

High load (–40 °F) (285 °F)

Mixers

LGBB 2 Wind turbine blade and yaw bearing Wind turbine blade and yaw slewing bearings –40 °C 120 °C L to M VL

grease (–40 °F) (250 °F)

Textile and machine tool spindles

LGLT 2 Low temperature, extremely high Small electric motors and robots –50 °C 110 °C L to M M to EH

speed (–60 °F) (230 °F)

Printing cylinders

Lubrication LGWM 1 Extreme pressure, low temperature Main shaft of wind turbines –30 °C 110 °C L to M L to M

Centralised lubrication systems

(230 °F)

(–20 °F)

Spherical roller thrust bearing applications

Main shaft of wind turbines

LGWM 2

Heavy duty off road or marine applications

High load, wide temperature

(–40 °F)

(230 °F)

Snow exposed applications –40 °C 110 °C L to M L to M

B.4

LGEM 2 High viscosity plus solid lubricants Jaw crushers –20 °C 120 °C M VL

Construction machinery

(–5 °F)

(250 °F)

Vibrating machinery

Trunnion bearings –10 °C 120 °C

Extremely high viscosity with solid

LGEV 2 Support and thrust rollers on rotary kilns and dryers M VL

lubricants (–15 °F) (250 °F)

Slewing ring bearings

Steel on steel plain bearings

LGHB 2 EP high viscosity, Dryer section of paper mills –20 °C 150 °C M to H VL to M

high temperature 5) Work roll bearings and continuous casting in steel industry (–5 °F) (300 °F)

Sealed spherical roller bearings up to 150 °C (300 °F)

Electric motors

LGHP 2 High performance polyurea grease Fans, even at high speed –40 °C 150 °C M to H M to H

(–40 °F)

(300 °F)

High speed ball bearings at medium and high temperatures

Bakery/brick oven equipment

LGED 2 High temperature Glass industry –30 °C 240 °C VH L to M

Harsh environment (–20 °F) (465 °F)

Vacuum pumps

Bakery equipment (ovens)

LGET 2 Extreme temperature Wafer baking machines –40 °C 260 °C VH L to M

Textile dryers (–40 °F) (500 °F)

1) LTL = Low Temperature Limit. Deined by means of the IP 186 Low temperature torque test. HTPL = High Temperature Performance Limit

2) mm 2 /s at 40 °C (105 °F) = cSt.

3) LGWA 2 can withstand peak temperatures of 220 °C (430 °F)

4) LGGB 2 can withstand peak temperatures of 120 °C (250 °F)

5) LGHB 2 can withstand peak temperatures of 200 °C (390 °F)

124