Page 127 - Rollingbearings

P. 127

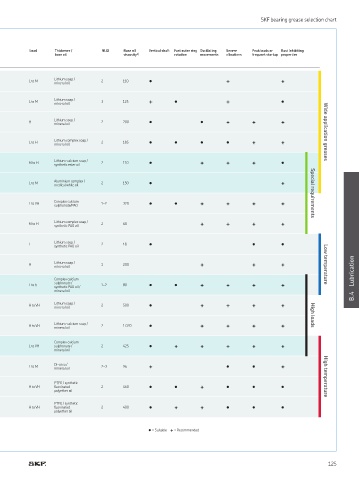

SKF bearing grease selection chart

Load Thickener / NLGI Base oil Vertical shaft Fast outer ring Oscillating Severe Peak loads or Rust inhibiting

base oil viscosity 2) rotation movements vibrations frequent startup properties

Lithium soap /

L to M 2 110 ● + +

mineral oil

Lithium soap /

L to M 3 125 + ● + ●

mineral oil

Lithium soap /

H 2 200 ● ● + + +

mineral oil

Lithium complex soap / Wide application greases

L to H 2 185 ● ● ● ● + +

mineral oil

Lithium-calcium soap /

M to H 2 110 ● + + + ●

synthetic ester oil

Aluminium complex /

L to M 2 150 ● +

medical white oil

Complex calcium Special requirements

L to VH 1–2 320 ● ● + + + +

sulphonate/PAO

Lithium complex soap /

M to H 2 68 + + + +

synthetic PAO oil

Lithium soap /

L 2 18 ● ● ●

synthetic PAO oil

Lithium soap /

H 1 200 + + + Low temperature

mineral oil Lubrication

Complex calcium

sulphonate /

L to h 1–2 80 ● ● + + + +

synthetic PAO oil /

mineral oil

B.4

Lithium soap /

H to VH 2 500 ● + + + +

mineral oil

Lithium-calcium soap / High loads

H to VH 2 1 020 ● + + + +

mineral oil

Complex calcium

L to VH sulphonate / 2 425 ● + + + + +

mineral oil

Di-urea /

L to M 2–3 96 + ● ● +

mineral oil

PTFE / synthetic High temperature

H to VH luorinated 2 460 ● ● + ● ● ●

polyether oil

PTFE / synthetic

H to VH luorinated 2 400 ● + + ● ● ●

polyether oil

● = Suitable + = Recommended

125