Page 119 - Rollingbearings

P. 119

Selecting a suitable grease

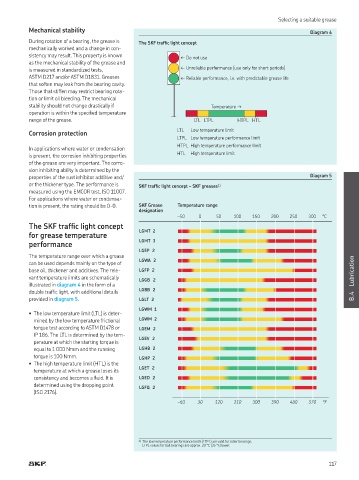

Mechanical stability Diagram 4

During rotation of a bearing, the grease is The SKF trafic light concept

mechanically worked and a change in con-

sistency may result. This property is known ← Do not use

as the mechanical stability of the grease and

is measured in standardized tests, ← Unreliable performance (use only for short periods)

ASTM D217 and/or ASTM D1831. Greases ← Reliable performance, i.e. with predictable grease life

that soften may leak from the bearing cavity.

Those that stiffen may restrict bearing rota-

tion or limit oil bleeding. The mechanical

stability should not change drastically if Temperature →

operation is within the speciied temperature

range of the grease. LTL LTPL HTPL HTL

LTL Low temperature limit

Corrosion protection

LTPL Low temperature performance limit

HTPL High temperature performance limit

In applications where water or condensation

is present, the corrosion inhibiting properties HTL High temperature limit

of the grease are very important. The corro-

sion inhibiting ability is determined by the

properties of the rust inhibitor additive and/ Diagram 5

or the thickener type. The performance is SKF trafic light concept – SKF greases 1)

measured using the EMCOR test, ISO 11007.

For applications where water or condensa-

tion is present, the rating should be 0-0. SKF Grease Temperature range

designation

–50 0 50 100 150 200 250 300 °C

The SKF trafic light concept

LGMT 2

for grease temperature

LGMT 3

performance

LGEP 2

The temperature range over which a grease

LGWA 2

can be used depends mainly on the type of

base oil, thickener and additives. The rele- LGFP 2 Lubrication

vant temperature limits are schematically

LGGB 2

illustrated in diagram 4 in the form of a

double trafic light, with additional details LGBB 2

provided in diagram 5. LGLT 2 B.4

LGWM 1

• The low temperature limit (LTL) is deter-

mined by the low temperature frictional LGWM 2

torque test according to ASTM D1478 or LGEM 2

IP 186. The LTL is determined by the tem-

perature at which the starting torque is LGEV 2

equal to 1 000 Nmm and the running LGHB 2

torque is 100 Nmm. LGHP 2

• The high temperature limit (HTL) is the

LGET 2

temperature at which a grease loses its

consistency and becomes a luid. It is LGED 2

determined using the dropping point

LGFQ 2

(ISO 2176).

–60 30 120 210 300 390 480 570 °F

1) The low temperature performance limits (LTPL) are valid for roller bearings

LTPL values for ball bearings are approx 20 °C (35 °F) lower

117