Page 114 - Rollingbearings

P. 114

B.4 Lubrication

Relubrication intervals Determining grease where

quantity for initial ill V = free volume in the bearing [cm 3 ]

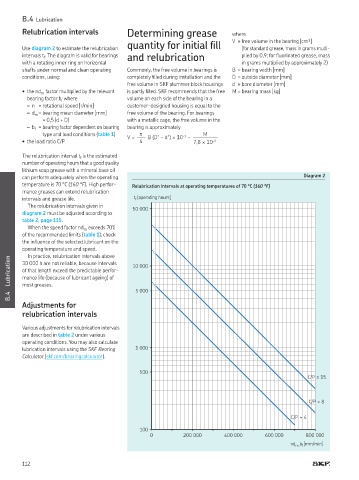

Use diagram 2 to estimate the relubrication (for standard grease, mass in grams multi-

intervals t . The diagram is valid for bearings and relubrication plied by 0,9; for luorinated grease, mass

f

with a rotating inner ring on horizontal in grams multiplied by approximately 2)

shafts under normal and clean operating Commonly, the free volume in bearings is B = bearing width [mm]

conditions, using: completely illed during installation and the D = outside diameter [mm]

free volume in SKF plummer block housings d = bore diameter [mm]

• the nd factor multiplied by the relevant is partly illed SKF recommends that the free M = bearing mass [kg]

m

bearing factor b where volume on each side of the bearing in a

f

– n = rotational speed [r/min] customer-designed housing is equal to the

– d = bearing mean diameter [mm] free volume of the bearing For bearings

m

= 0,5 (d + D) with a metallic cage, the free volume in the

– b = bearing factor dependent on bearing bearing is approximately

f

type and load conditions (table 1) π 2 2 -3 M

V = —– B (D – d ) × 10 – –––––––––

• the load ratio C/P 4 7,8 × 10

-3

The relubrication interval t is the estimated

f

number of operating hours that a good quality

lithium soap grease with a mineral base oil

can perform adequately when the operating Diagram 2

temperature is 70 °C (160 °F) High perfor- Relubrication intervals at operating temperatures of 70 °C (160 °F)

mance greases can extend relubrication

intervals and grease life t [operating hours]

f

The relubrication intervals given in 50 000

diagram 2 must be adjusted according to

table 2, page 115

When the speed factor nd exceeds 70%

m

of the recommended limits (table 1), check

the inluence of the selected lubricant on the

operating temperature and speed

In practice, relubrication intervals above

Lubrication 30 000 h are not reliable, because intervals 10 000

of that length exceed the predictable perfor-

mance life (because of lubricant ageing) of

B.4 most greases 5 000

Adjustments for

relubrication intervals

Various adjustments for relubrication intervals

are described in table 2 under various

operating conditions You may also calculate

lubrication intervals using the SKF Bearing 1 000

Calculator (skf com/bearingcalculator)

500

C/P ≥ 15

C/P ≈ 8

C/P ≈ 4

100

0 200 000 400 000 600 000 800 000

nd b [mm/min]

m f

112