Page 115 - Rollingbearings

P. 115

Selecting grease or oil

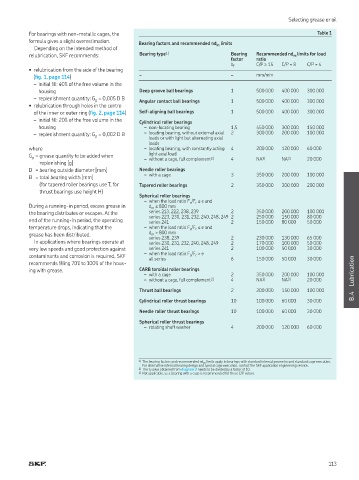

For bearings with non-metallic cages, the Table 1

formula gives a slight overestimation. Bearing factors and recommended nd m limits

Depending on the intended method of

relubrication, SKF recommends: Bearing type 1) Bearing Recommended nd limits for load

m

factor ratio

b f C/P ≥ 15 C/P ≈ 8 C/P ≈ 4

• relubrication from the side of the bearing

(ig. 1, page 114) – – mm/min

– initial ill: 40% of the free volume in the

housing Deep groove ball bearings 1 500 000 400 000 300 000

– replenishment quantity: G = 0,005 D B Angular contact ball bearings 1 500 000 400 000 300 000

p

• relubrication through holes in the centre

of the inner or outer ring (ig. 2, page 114) Self-aligning ball bearings 1 500 000 400 000 300 000

– initial ill: 20% of the free volume in the

Cylindrical roller bearings

housing – non-locating bearing 1,5 450 000 300 000 150 000

– replenishment quantity: G = 0,002 D B – locating bearing, without external axial 2 300 000 200 000 100 000

p

loads or with light but alternating axial

loads

where – locating bearing, with constantly acting 4 200 000 120 000 60 000

light axial load

G = grease quantity to be added when – without a cage, full complement 2) 4 NA 3) NA 3) 20 000

p

replenishing [g]

D = bearing outside diameter [mm] Needle roller bearings

– with a cage 3 350 000 200 000 100 000

B = total bearing width [mm]

(for tapered roller bearings use T, for Tapered roller bearings 2 350 000 300 000 200 000

thrust bearings use height H)

Spherical roller bearings

– when the load ratio F a /F r ≤ e and

During a running-in period, excess grease in d ≤ 800 mm

m

the bearing distributes or escapes. At the series 213, 222, 238, 239 2 350 000 200 000 100 000

series 223, 230, 231, 232, 240, 248, 249 2

250 000

80 000

150 000

end of the running-in period, the operating series 241 2 150 000 80 000 50 000

temperature drops, indicating that the – when the load ratio F /F ≤ e and

a

r

m

grease has been distributed. d > 800 mm

series 238, 239 2 230 000 130 000 65 000

In applications where bearings operate at series 230, 231, 232, 240, 248, 249 2 170 000 100 000 50 000

very low speeds and good protection against series 241 2 100 000 50 000 30 000

a

r

contaminants and corrosion is required, SKF – when the load ratio F /F > e 6 150 000 50 000 30 000

all series

recommends illing 70% to 100% of the hous-

ing with grease. CARB toroidal roller bearings Lubrication

– with a cage 2 350 000 200 000 100 000

– without a cage, full complement 2) 4 NA 3) NA 3) 20 000

Thrust ball bearings 2 200 000 150 000 100 000

B.4

Cylindrical roller thrust bearings 10 100 000 60 000 30 000

Needle roller thrust bearings 10 100 000 60 000 30 000

Spherical roller thrust bearings

– rotating shaft washer 4 200 000 120 000 60 000

1) The bearing factors and recommended nd m limits apply to bearings with standard internal geometry and standard cage execution.

For alternative internal bearing design and special cage execution, contact the SKF application engineering service.

2) The t f value obtained from diagram 2 needs to be divided by a factor of 10.

3) Not applicable, as a bearing with a cage is recommended for these C/P values.

113