Page 10 - SKF-Food-Line-ball-bearing-units

P. 10

Bearing grease Allergens and allergen categories

• Cereals containing gluten, namely: wheat

All units are lubricated for life with NSF-approved, SKF food-grade (such as spelt and khorasan wheat), rye,

barley, oats

grease for relubrication-free operation The high-quality grease is • Crustaceans for example prawns, crabs,

lobster, crayfish

registered by NSF as a category H1 (lubricant acceptable for use in • Eggs Product introduction

• Fish

applications where there is potential for incidental food contact) • Peanuts

• Soybeans

• Milk (including lactose)

• Nuts; namely almonds, hazelnuts, walnuts,

cashews, pecan nuts, Brazil nuts, pistachio

nuts, macadamia (or Queensland) nuts

• Celery (including celeriac)

• Mustard

The grease has been selected because it The technical specifications of this grease • Sesame A

provides good resistance to the separation of are listed in table 2 • Sulphur dioxide/sulphites, where added

and at a level above 10 mg/kg or 10 mg/L

the base oil and the thickener in the pres- in the finished product This can be used as

ence of detergent Greases without this The grease contains no ingredients from the a preservative in dried fruit

enhanced resistance can separate, resulting 14 allergens and allergen categories that • Lupin, which includes lupin seeds and flour

and can be found in types of bread, pas-

in loss of oil past the seal, then loss of lubri- must be declared in food products and is tries and pasta

cation to the seal lips also free from traces of beef, pork and • Molluscs like, mussels, whelks, oysters,

chicken Additional certifications for the snails and squid

This can lead to scoring damage to the mat- grease have been secured from AMERICAN

ing surface on the inner ring shoulder The HALAL FOUNDATION (AHF) and 1K Kosher

NSF registration confirms this SKF grease

fulfils the requirements listed in the US Food

and Drug Administration’s guidelines under

21 CFR section 178 3570

Table 2

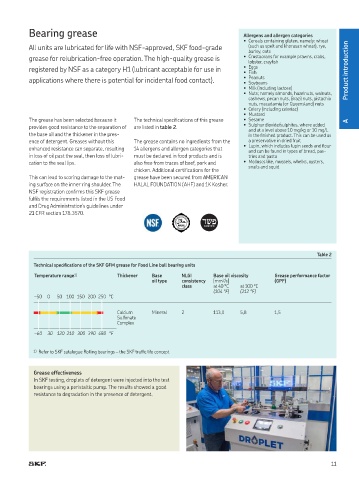

Technical specifications of the SKF GFM grease for Food Line ball bearing units

Temperature range 1) Thickener Base NLGI Base oil viscosity Grease performance factor

oil type consist ency [mm 2 /s] (GPF)

class at 40 °C at 100 °C

(104 °F) (212 °F)

–50 0 50 100 150 200 250 °C

Calcium Mineral 2 113,0 5,8 1,5

Sulfonate

Complex

–60 30 120 210 300 390 480 °F

1) Refer to SKF catalogue Rolling bearings – the SKF traffic life concept

Grease effectiveness

In SKF testing, droplets of detergent were injected into the test

bearings using a peristaltic pump The results showed a good

resistance to degradation in the presence of detergent

11 11