Page 8 - SKF-Food-Line-ball-bearing-units

P. 8

End cover

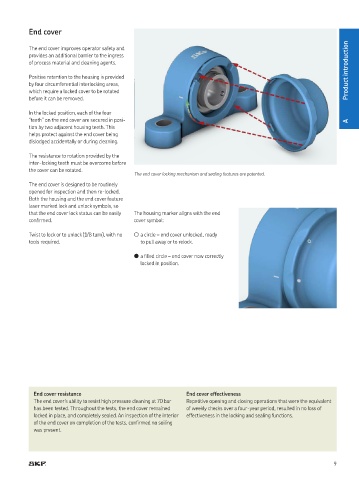

The end cover improves operator safety and

provides an additional barrier to the ingress

of process material and cleaning agents

Positive retention to the housing is provided Product introduction

by four circumferential interlocking areas,

which require a locked cover to be rotated

before it can be removed

In the locked position, each of the four

“teeth” on the end cover are secured in posi- A

tion by two adjacent housing teeth This

helps protect against the end cover being

dislodged accidentally or during cleaning

The resistance to rotation provided by the

inter-locking teeth must be overcome before

the cover can be rotated

The end cover locking mechanism and sealing features are patented.

The end cover is designed to be routinely

opened for inspection and then re-locked

Both the housing and the end cover feature

laser marked lock and unlock symbols, so

that the end cover lock status can be easily The housing marker aligns with the end

confirmed cover symbol:

Twist to lock or to unlock (1/8 turn), with no ○ a circle – end cover unlocked, ready

tools required to pull away or to relock

● a filled circle – end cover now correctly

locked in position

End cover resistance End cover effectiveness

The end cover’s ability to resist high pressure cleaning at 70 bar Repetitive opening and closing operations that were the equivalent

has been tested Throughout the tests, the end cover remained of weekly checks over a four-year period, resulted in no loss of

locked in place, and completely sealed An inspection of the interior effectiveness in the locking and sealing functions

of the end cover on completion of the tests, confirmed no soiling

was present

9