Page 27 - Rollingbearings

P. 27

Components and materials

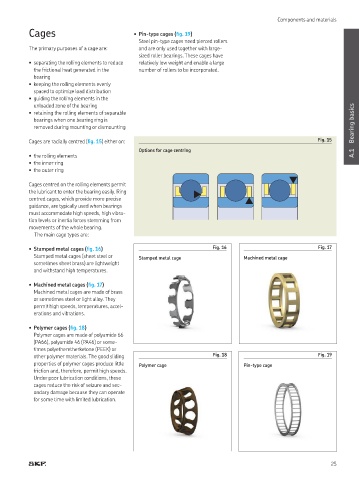

Cages • Pin-type cages (ig. 19)

Steel pin-type cages need pierced rollers

The primary purposes of a cage are: and are only used together with large-

sized roller bearings. These cages have

• separating the rolling elements to reduce relatively low weight and enable a large

the frictional heat generated in the number of rollers to be incorporated.

bearing

• keeping the rolling elements evenly

spaced to optimize load distribution

• guiding the rolling elements in the

unloaded zone of the bearing

• retaining the rolling elements of separable

bearings when one bearing ring is Bearing basics

removed during mounting or dismounting

Cages are radially centred (ig. 15) either on: Fig. 15

Options for cage centring A.1

• the rolling elements

• the inner ring

• the outer ring

Cages centred on the rolling elements permit

the lubricant to enter the bearing easily. Ring

centred cages, which provide more precise

guidance, are typically used when bearings

must accommodate high speeds, high vibra-

tion levels or inertia forces stemming from

movements of the whole bearing.

The main cage types are:

• Stamped metal cages (ig. 16) Fig. 16 Fig. 17

Stamped metal cages (sheet steel or Stamped metal cage Machined metal cage

sometimes sheet brass) are lightweight

and withstand high temperatures.

• Machined metal cages (ig. 17)

Machined metal cages are made of brass

or sometimes steel or light alloy. They

permit high speeds, temperatures, accel-

erations and vibrations.

• Polymer cages (ig. 18)

Polymer cages are made of polyamide 66

(PA66), polyamide 46 (PA46) or some-

times polyetheretherketone (PEEK) or

other polymer materials. The good sliding Fig. 18 Fig. 19

properties of polymer cages produce little Polymer cage Pin-type cage

friction and, therefore, permit high speeds.

Under poor lubrication conditions, these

cages reduce the risk of seizure and sec-

ondary damage because they can operate

for some time with limited lubrication.

25