Page 154 - Rollingbearings

P. 154

B.6 Bearing interfaces

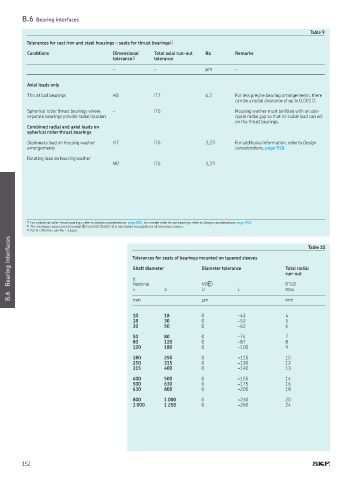

Table 9

Tolerances for cast iron and steel housings – seats for thrust bearings 1)

Conditions Dimensional Total axial run-out Ra Remarks

tolerance 2) tolerance

– – µm –

Axial loads only

Thrust ball bearings H8 IT7 6,3 For less precise bearing arrangements, there

can be a radial clearance of up to 0,001 D.

Spherical roller thrust bearings where – IT6 Housing washer must be itted with an ade-

separate bearings provide radial location quate radial gap so that no radial load can act

on the thrust bearings.

Combined radial and axial loads on

spherical roller thrust bearings

Stationary load on housing washer H7 IT6 3,2 3) For additional information, refer to Design

arrangements considerations, page 918.

Rotating load on housing washer

M7 IT6 3,2 3)

1) For cylindrical roller thrust bearings, refer to Design considerations, page 885. For needle roller thrust bearings, refer to Design considerations, page 903.

2) The envelope requirement (symbol � from ISO 144051) is not shown but applies to all tolerance classes.

3) For D < 80 mm, use Ra = 1,6 µm.

Bearing interfaces Tolerances for seats of bearings mounted on tapered sleeves Total radial Table 10

Diameter tolerance

Shaft diameter

run-out

d

Nominal

max.

> ≤ h9� L IT5/2

U

B.6 mm µm mm

10 18 0 –43 4

18 30 0 –52 5

30 50 0 –62 6

50 80 0 –74 7

80 120 0 –87 8

120 180 0 –100 9

180 250 0 –115 10

250 315 0 –130 12

315 400 0 –140 13

400 500 0 –155 14

500 630 0 –175 16

630 800 0 –200 18

800 1 000 0 –230 20

1 000 1 250 0 –260 24

152