Page 153 - Rollingbearings

P. 153

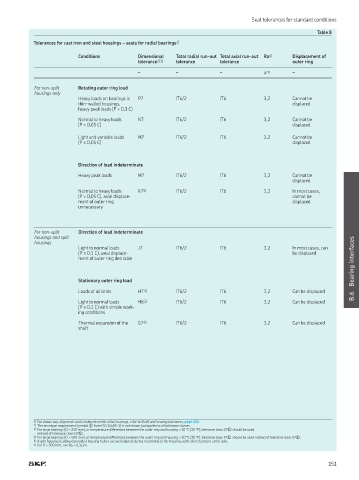

Seat tolerances for standard conditions

Table 8

Tolerances for cast iron and steel housings – seats for radial bearings 1)

Conditions Dimensional Total radial run-out Total axial run-out Ra 6) Displacement of

tolerance 2)3) tolerance tolerance outer ring

– – – µm –

For non-split Rotating outer ring load

housings only

Heavy loads on bearings in P7 IT6/2 IT6 3,2 Cannot be

thin-walled housings, displaced

heavy peak loads (P > 0,1 C)

Normal to heavy loads N7 IT6/2 IT6 3,2 Cannot be

(P > 0,05 C) displaced

Light and variable loads M7 IT6/2 IT6 3,2 Cannot be

(P ≤ 0,05 C) displaced

Direction of load indeterminate

Heavy peak loads M7 IT6/2 IT6 3,2 Cannot be

displaced

Normal to heavy loads K7 5) IT6/2 IT6 3,2 In most cases,

(P > 0,05 C), axial displace- cannot be

ment of outer ring displaced

unnecessary

For non-split Direction of load indeterminate

housings and split

housings

Light to normal loads J7 IT6/2 IT6 3,2 In most cases, can

(P ≤ 0,1 C), axial displace- be displaced

ment of outer ring desirable Bearing interfaces

Stationary outer ring load

Loads of all kinds H7 3) IT6/2 IT6 3,2 Can be displaced B.6

Light to normal loads H8 3) IT6/2 IT6 3,2 Can be displaced

(P ≤ 0,1 C) with simple work-

ing conditions

Thermal expansion of the G7 4) IT6/2 IT6 3,2 Can be displaced

shaft

1) For drawn cup, alignment and combined needle roller bearings, refer to Shaft and housing tolerances, page 610

2) The envelope requirement (symbol � from ISO 14405-1) is not shown but applies to all tolerance classes

3) For large bearings (D > 250 mm), or temperature differences between the outer ring and housing > 10 °C (18 °F), tolerance class G7� should be used

instead of tolerance class H7�

4) For large bearings (D > 500 mm), or temperature differences between the outer ring and housing > 10 °C (18 °F), tolerance class F7� should be used instead of tolerance class G7�

5) A split housing is allowed provided housing halves are well aligned during machining of the housing, with relief chamfers at the split

6) For D > 500 mm, use Ra = 6,3 µm

151