Page 151 - Rollingbearings

P. 151

Seat tolerances for standard conditions

Bearings with a • Self-aligning ball bearings, page 438

tapered bore • Spherical roller bearings, page 774

• CARB toroidal roller bearings, page 842

Bearings with a tapered bore are always For seats of bearings mounted on tapered

mounted with an interference it for the sleeves, wider diameter tolerances are per-

inner ring The it is determined by the dis- missible The total run-out tolerances should

tance through which the inner ring is driven be the same as for bearings on cylindrical

up on a tapered seat or sleeve For detailed seats (Tolerances for bearing seats and abut-

information, refer to the information in the ments, page 144)

product sections: Suitable tolerances are listed in table 10,

page 152 They are valid for moderate

speeds and moderate precision

requirements

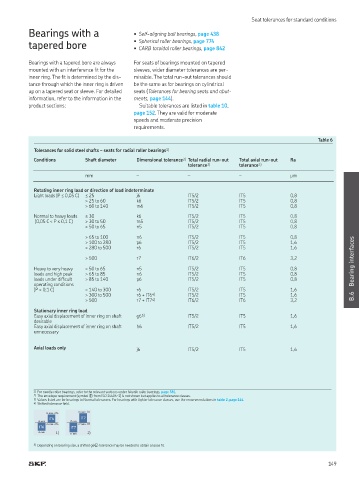

Table 6

Tolerances for solid steel shafts – seats for radial roller bearings 1)

Conditions Shaft diameter Dimensional tolerance 2) Total radial run-out Total axial run-out Ra

tolerance 3) tolerance 3)

mm – – – µm

Rotating inner ring load or direction of load indeterminate

Light loads (P ≤ 0,05 C) ≤ 25 j6 IT5/2 IT5 0,8

> 25 to 60 k6 IT5/2 IT5 0,8

> 60 to 140 m6 IT5/2 IT5 0,8

Normal to heavy loads ≤ 30 k6 IT5/2 IT5 0,8

(0,05 C < P ≤ 0,1 C) > 30 to 50 m5 IT5/2 IT5 0,8

> 50 to 65 n5 IT5/2 IT5 0,8

> 65 to 100 n6 IT5/2 IT5 0,8

> 100 to 280 p6 IT5/2 IT5 1,6

> 280 to 500 r6 IT5/2 IT5 1,6

> 500 r7 IT6/2 IT6 3,2 Bearing interfaces

Heavy to very heavy > 50 to 65 n5 IT5/2 IT5 0,8

loads and high peak > 65 to 85 n6 IT5/2 IT5 0,8

loads under dificult > 85 to 140 p6 IT5/2 IT5 0,8

operating conditions

(P > 0,1 C) > 140 to 300 r6 IT5/2 IT5 1,6

> 300 to 500 r6 + IT6 4) IT5/2 IT5 1,6 B.6

> 500 r7 + IT7 4) IT6/2 IT6 3,2

Stationary inner ring load

Easy axial displacement of inner ring on shaft g6 5) IT5/2 IT5 1,6

desirable

Easy axial displacement of inner ring on shaft h6 IT5/2 IT5 1,6

unnecessary

Axial loads only j6 IT5/2 IT5 1,6

1) For needle roller bearings, refer to the relevant sections under Needle roller bearings, page 581

2) The envelope requirement (symbol � from ISO 14405-1) is not shown but applies to all tolerance classes

3) Values listed are for bearings to Normal tolerances For bearings with tighter tolerance classes, use the recommendations in table 2, page 144

4) Shifted tolerance ield

r6 max + IT6 r7 max + IT7

IT6 IT7

r6 max r7 max

r6 min + IT6 r7 min + IT7

IT6 IT7

r6 min 1) r7 min 2)

5) Depending on bearing size, a shifted g6� tolerance may be needed to obtain a loose it

149