Page 580 - EMUGE

P. 580

Spiralbohrer · Twist Drills

Product

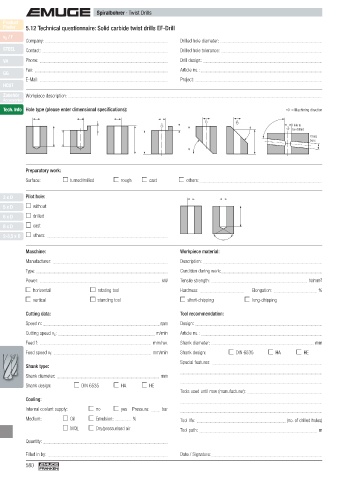

Finder 5.12 Technical questionnaire: Solid carbide twist drills EF-Drill

v c / f

Company: ..................................................................................................................................................... Drilled hole diameter: ............................................................................................................................

STEEL

Contact: ......................................................................................................................................................... Drilled hole tolerance: ...........................................................................................................................

VA Phone: ............................................................................................................................................................ Drill design: .................................................................................................................................................

Fax: .................................................................................................................................................................. Article no.: ....................................................................................................................................................

GG

E-Mail: ............................................................................................................................................................ Project: ...........................................................................................................................................................

HCUT

Zubehör Workpiece description: .....................................................................................................................................................................................................................................................................................................................

Accessories

Tech. Info Hole type (please enter dimensional specifi cations): = Machining direction

Hole to

be drilled

Cross

bore

Preparatory work:

Surface: turned/milled rough cast others: .....................................................................................................................................................

3 x D Pilot hole:

5 x D without

6 x D drilled

8 x D cast

2-3,5 x D others: ...................................................................................................................................................

Maschine: Workpiece material:

Manufacturer: ............................................................................................................................................ Description: .................................................................................................................................................

Type: ................................................................................................................................................................ Condition during work: ...........................................................................................................................

Power: ................................................................................................................................................... kW Tensile strength: ..................................................................................................................... N/mm 2

horizontal rotating tool Hardness: ...................................................... Elongation: ..................................................... %

vertical standing tool short-chipping long-chipping

Cutting data: Tool recommendation:

Speed n: ...............................................................................................................................................rpm Design: ...........................................................................................................................................................

Cutting speed v c : ..................................................................................................................... m/min Article no.: ...................................................................................................................................................

Feed f: ........................................................................................................................................ mm/rev. Shank diameter: ............................................................................................................................. mm

Feed speed v f : ....................................................................................................................... mm/min Shank design: DIN 6535 HA HE

Special features: ......................................................................................................................................

Shank type:

.............................................................................................................................................................................

Shank diameter: ............................................................................................................................. mm

.............................................................................................................................................................................

Shank design: DIN 6535 HA HE

Tools used until now (manufacturer): ...........................................................................................

Cooling:

.............................................................................................................................................................................

Internal coolant supply: no yes Pressure: ........... bar

.............................................................................................................................................................................

Medium: Oil Emulsion: ................... % Tool life: ............................................................................................................. (no. of drilled holes)

MQL Dry/pressurised air Tool path: ................................................................................................................................................ m

Quantity: ........................................................................................................................................................

Filled in by: .................................................................................................................................................. Date / Signature: .......................................................................................................................................

580