Page 33 - EMUGE

P. 33

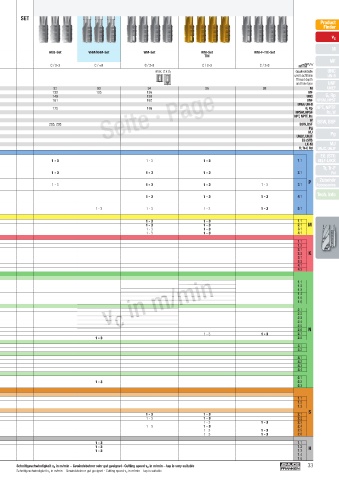

SET

Product

Finder

v c

M

Enorm Enorm Enorm Enorm Rekord Rekord Rekord Rekord Rekord Rekord Enorm Enorm HGB-Set VHM/KHM-Set WM-Set WM-Set WM-F-TIC-Set

Z/E-IKZ Z/E-IKZ Z50 Z50 A-SPEED A-SPEED A-SPEED/E A-SPEED/E B-Z-SPEED B-Z-SPEED-IKZN Z-SPEED-X Z-SPEED-X-IKZ TIN

TIN TIN IKZ-TICN IKZN-TICN IKZ-TICN IKZN-TICN PM-TIN-70 PM-TIN-70 PM-TIN-60 PM-TIN-60 MF

E / 1,5-2 E / 1,5-2 C / 2-3 C / 2-3 C / 2-3 C / 2-3 E / 1,5-2 E / 1,5-2 B / 4-5 B / 4-5 C / 2-3 C / 2-3 C / 2-3 C / ≈3 C / 2-3 C / 2-3 C / 2-3

Gewindetiefe max. 3 x d 1 max. 2 x d 1 max. 2 x d 1 max. 2 x d 1 max. 2 x d 1 max. 3 x d 1 max. 3 x d 1 max. 2 x d 1 Gewindetiefe UNC

und Lochform und Lochform UN-8

Thread depth Thread depth

and hole type 1) 1) and hole type UNF

Seite · Page

Seite · Page

Seite · Page

Seite · Page

Seite · Page

Seite · Page

Seite · Page

Seite · Page

Seite · Page

Seite · Page

Seite · Page

Seite · Page

Seite · Page

Seite · Page

Seite · Page

Seite · Page

M 59 59, 81 59, 82 59, 82 60, 83 60, 83 60, 83 60, 83 61, 83 61, 83 61, 83 61, 83 92 93 94 96 98 M UNEF

MF 124 124 125 125 125 125 125 125 125 125 132 135 136 MF

UNC 149 150 UNC G, Rp

UNF 161 162 UNF NPSM, NPSF

UNEF, UN-8 UNEF, UN-8

176

G, Rp 175 176176 G, Rp NPT, NPTF

NPSM, NPSF Seite · Page NPSM, NPSF Rc, W

NPT, NPTF, Rc NPT, NPTF, Rc

W W BSW, BSF

BSW, BSF 205, 208 BSW, BSF

Pg Pg

MJ MJ Pg

UNJC, UNJF UNJC, UNJF

EG (STI) EG (STI)

LK-M LK-M MJ

Tr, Tr-F, Rd Tr, Tr-F, Rd UNJC, UNJF

EG (STI)

1.1 5 - 25 15 - 45 5 - 25 15 - 45 40 - 80 40 - 80 1 - 3 1 - 3 1 - 3 1.1 SELF-LOCK

Tr, Tr-F

2.1 5 - 20 10 - 40 5 - 20 10 - 40 30 - 60 30 - 60 30 - 60 30 - 60 1 - 3 1 - 3 1 - 3 2.1 Rd

P 3.1 2 - 15 5 - 25 2 - 15 5 - 25 20 - 40 20 - 40 20 - 40 20 - 40 1 - 3 1 - 3 1 - 3 1 - 3 3.1 P Zubehör

Accessories

Tech. Info

4.1 2 - 10 5 - 20 2 - 10 5 - 20 10 - 30 10 - 30 10 - 30 10 - 30 1 - 3 1 - 3 1 - 3 4.1

5.1 1 - 3 1 - 3 1 - 3 1 - 3 5.1

1.1 2 - 10 5 - 20 2 - 10 5 - 20 1 - 3 1 - 3 1.1

M 2.1 2 - 10 5 - 20 2 - 10 5 - 20 1 - 3 1 - 3 2.1 M

3.1 5 - 15 5 - 15 1 - 3 1 - 3 3.1

4.1 1 - 3 1 - 3 4.1

1.1 40 - 80 40 - 80 40 - 80 40 - 80 1.1

1.2 30 - 60 30 - 60 30 - 60 30 - 60 1.2

2.1 30 - 60 30 - 60 30 - 60 30 - 60 30 - 60 30 - 60 2.1

K 2.2 20 - 40 20 - 40 20 - 40 20 - 40 20 - 40 20 - 40 2.2 K

3.1 20 - 40 20 - 40 20 - 40 20 - 40 3.1

3.2 20 - 40 20 - 40 20 - 40 20 - 40 3.2

4.1 40 - 80 40 - 80 40 - 80 40 - 80 4.1

4.2 30 - 60 30 - 60 30 - 60 30 - 60 4.2

in m/min

in m/min

in m/min

in m/min

in m/min

in m/min

in m/min

in m/min

in m/min

in m/min

in m/min

in m/min

in m/min

in m/min

in m/min

in m/min

in m/min

in m/min

in m/min

in m/min

in m/min

in m/min

in m/min

in m/min

in m/min

in m/min

in m/min

in m/min

in m/min

in m/min

in m/min

in m/min

in m/min

in m/min

in m/min

in m/min

in m/min

in m/min

in m/min

in m/min

1.1 1.1

1.2 1.2

1.3 1.3

1.4 15 - 40 15 - 40 20 - 60 20 - 60 20 - 60 20 - 60 20 - 60 20 - 60 1.4

1.5 15 - 40 15 - 40 20 - 60 20 - 60 20 - 60 20 - 60 20 - 60 20 - 60 in m/min 1.5

v

v

v

1.6 10 - 30 10 - 30 20 - 40 20 - 40 20 - 40 20 - 40 20 - 40 20 - 40 1.6

v

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

2.1 5 - 20 5 - 30 5 - 20 5 - 30 2.1

2.2 20 - 60 20 - 60 v 2.2

2.3 c 2.3

2.4 5 - 25 5 - 25 2.4

2.5 5 - 25 5 - 25 2.5

N 2.6 2.6 N

2.7 1 - 3 1 - 3 2.7

2.8 1 - 3 2.8

3.1 3.1

3.2 3.2

4.1 4.1

4.2 4.2

4.3 4.3

4.4 4.4

5.1 5.1

5.2 1 - 3 5.2

5.3 5.3

1.1 5 - 15 5 - 15 1.1

1.2 1.2

1.3 1.3

S 2.1 1 - 3 1 - 3 2.1 S

2.2 1 - 3 1 - 3 2.2

2.3 1 - 3 1 - 3 2.3

2.4 1 - 3 1 - 3 2.4

2.5 1 - 3 1 - 3 2.5

2.6 1 - 3 1 - 3 2.6

1.1 1 - 3 1.1

H 1.2 1 - 3 1.2 H

1.3

1.3

1 - 3

1.4 1.4

1.5 1.5

Schnittgeschwindigkeit v c in m/min – Gewindebohrer sehr gut geeignet · Cutting speed v c in m/min – tap is very suitable 33

Schnittgeschwindigkeit v c in m/min – Gewindebohrer gut geeignet · Cutting speed v c in m/min – tap is suitable