Page 99 - Single-line automatic lubrication systems

P. 99

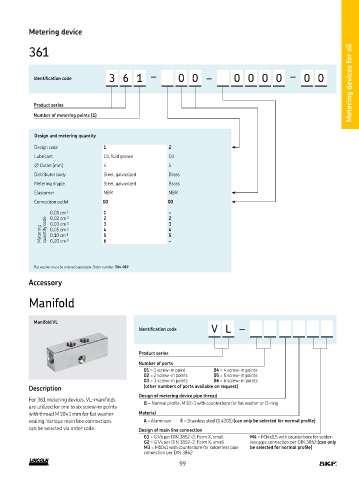

Metering device

Metering devices for oil

361

3 6 1 – 0 0 – 0 0 0 0 – 0 0

Identification code

Product series

Number of metering points (1)

Design and metering quantity

Design code 1 2

Lubricant Oil, fluid grease Oil

∅ Outlet [mm] 4 4

Distributor body Steel, galvanized Brass

Metering nipple Steel, galvanized Brass

Elastomer NBR NBR

Connection outlet 00 00

0,01 cm 3 1 2 – 2

0,02 cm 3

Metering quantity code 0,03 cm 3 3 4 5 6 3 4 5 –

0,05 cm 3

0,10 cm 3

0,20 cm 3

Flat washer must be ordered separately. Order number: 504-019

Accessory

Manifold

Manifold VL

V L –

Identification code

Product series

Number of ports

01 = 1 screw-in point 04 = 4 screw-in points

02 = 2 screw-in points 05 = 5 screw-in points

03 = 3 screw-in points 06 = 6 screw-in points

Description (other numbers of ports available on request)

Design of metering device pipe thread

For 361 metering devices, VL-manifolds

are utilized for one to six screw-in points B = Normal profile, M 10×1 with counterbore for flat washer or O-ring

with thread M 10×1 mm for flat washer Material

sealing. Various main line connections A = Aluminum E = Stainless steel (1.4305) (can only be selected for normal profile)

can be selected via order code. Design of main line connection

G1 = G 1 /8 per DIN 3852-2, Form X, small M4 = M14x1,5 with counterbore for solder-

G2 = G 1 /4 per DIN 3852-2, Form X, small less pipe connection per DIN 3862 (can only

M3 = M10x1 with counterbore for solderless pipe be selected for normal profile)

connection per DIN 3862

99