Page 96 - Single-line automatic lubrication systems

P. 96

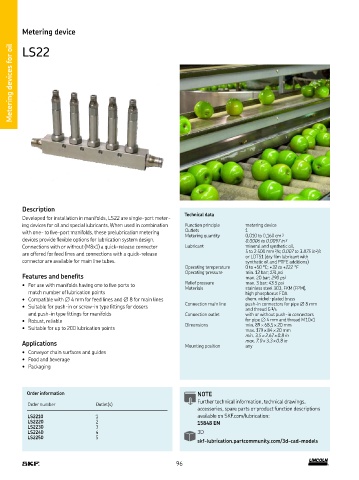

Metering device

Metering devices for oil

LS22

Description

Technical data

Developed for installation in manifolds, LS22 are single-port meter-

ing devices for oil and special lubricants. When used in combination Function principle metering device

with one- to five-port manifolds, these prelubrication metering Outlets 1

Metering quantity 0,010 to 0,160 cm 3

devices provide flexible options for lubrication system design. 0.0006 to 0.0097 in 3

Connections with or without (M8x1) a quick-release connector Lubricant mineral and synthetic oil,

5 to 2 500 mm 2 /s; 0.007 to 3.875 in 2 /s

are offered for feed lines and connections with a quick-release or LDTS1 (dry film lubricant with

connector are available for main line tubes. synthetic oil and PTFE additions)

Operating temperature 0 to +50 °C; +32 to +122 °F

Operating pressure min. 12 bar; 174 psi

Features and benefits max. 20 bar; 290 psi

• For use with manifolds having one to five ports to Relief pressure max. 3 bar; 43.5 psi

stainless steel 303, FKM (FPM),

Materials

match number of lubrication points high phosphorus FDA

• Compatible with ∅ 4 mm for feed lines and ∅ 8 for main lines chem. nickel-plated brass

Connection main line push-in connectors for pipe ∅ 8 mm

• Suitable for push-in or screw-in type fittings for dosers

and thread G 1 /4

and push-in type fittings for manifolds Connection outlet with or without push-in connectors

• Robust, reliable for pipe ∅ 4 mm and thread M 10x1

• Suitable for up to 200 lubrication points Dimensions min. 89 × 68,5 × 20 mm

max. 179 × 84 × 20 mm

min. 3.5 × 2.67 × 0.8 in

Applications Mounting position max. 7.0 × 3.3 × 0.8 in

any

• Conveyor chain surfaces and guides

• Food and beverage

• Packaging

Order information NOTE

Further technical information, technical drawings,

Order number Outlet(s)

accessories, spare parts or product function descriptions

LS2210 1 available on SKF.com/lubrication:

LS2220 2 15848 EN

LS2230 3

LS2240 4 3D

LS2250 5

skf-lubrication partcommunity com/3d-cad-models

96

96