Page 103 - Single-line automatic lubrication systems

P. 103

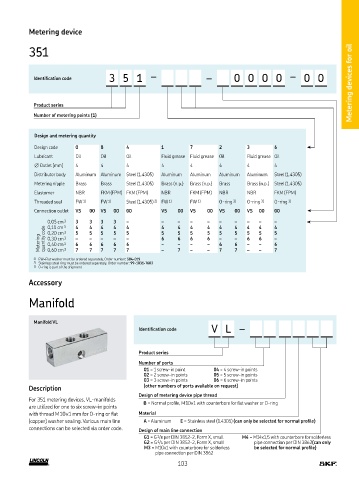

Metering device

Metering devices for oil

351

3 5 1 – – 0 0 0 0 – 0 0

Identification code

Product series

Number of metering points (1)

Design and metering quantity

Design code 0 8 4 1 7 2 3 6

Lubricant Oil Oil Oil Fluid grease Fluid grease Oil Fluid grease Oil

∅ Outlet [mm] 4 4 4 4 4 4 4 4

Distributor body Aluminum Aluminum Steel (1.4305) Aluminum Aluminum Aluminum Aluminum Steel (1.4305)

Metering nipple Brass Brass Steel (1.4305) Brass (n.p.) Brass (n.p.) Brass Brass (n.p.) Steel (1.4305)

Elastomer NBR FKM (FPM) FKM (FPM) NBR FKM (FPM) NBR NBR FKM (FPM)

Threaded seal FW 1) FW 1) Steel (1.4305) 2) FW 1) FW 1) O-ring 3) O-ring 3) O-ring 3)

Connection outlet VS 00 VS 00 00 VS 00 VS 00 VS 00 VS 00 00

0,05 cm 3 3 3 3 4 3 – 4 – 4 – 4 – 4 – 4 – 4 – 4 – 4 – 4 – 4

0,10 cm 3

4

4

4

Metering quantity code 0,20 cm 3 5 5 5 – 6 7 5 5 – 6 7 5 6 – – 5 6 – 7 5 5 6 – – 5 – 6 7 5 – 6 7 5 6 – – 5 5 – 6 7

0,30 cm 3

–

–

–

6

6

6

–

–

6

6

0,40 cm 3

–

7

–

7

0,60 cm 3

7

1) FW=Flat washer must be ordered separately. Order number: 504-019

2) Stainless steel ring must be ordered separately. Order number: 99-1031-7603

3) O-ring is part of the shipment

Accessory

Manifold

Manifold VL

V L –

Identification code

Product series

Number of ports

01 = 1 screw-in point 04 = 4 screw-in points

02 = 2 screw-in points 05 = 5 screw-in points

03 = 3 screw-in points 06 = 6 screw-in points

Description (other numbers of ports available on request)

Design of metering device pipe thread

For 351 metering devices, VL-manifolds B = Normal profile, M 10×1 with counterbore for flat washer or O-ring

are utilized for one to six screw-in points

with thread M 10×1 mm for O-ring or flat Material

(copper) washer sealing. Various main line A = Aluminum E = Stainless steel (1.4305) (can only be selected for normal profile)

connections can be selected via order code.

Design of main line connection

G1 = G 1 /8 per DIN 3852-2, Form X, small M4 = M14x1,5 with counterbore for solderless

G2 = G 1 /4 per DIN 3852-2, Form X, small pipe connection per DIN 3862(can only

M3 = M10x1 with counterbore for solderless be selected for normal profile)

pipe connection per DIN 3862

103