Page 140 - Single-line automatic lubrication systems

P. 140

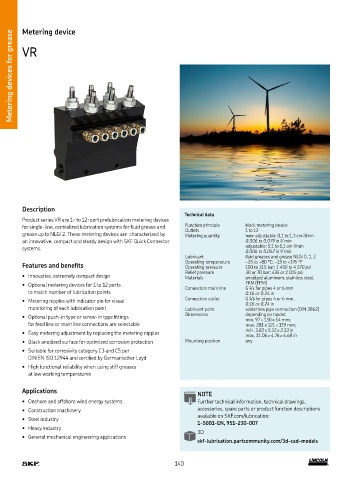

Metering devices for grease Metering device

VR

Description

Technical data

Product series VR are 1- to 12-port prelubrication metering devices

for single-line, centralized lubrication systems for fluid grease and Function principle block metering device

Outlets 1 to 12

grease up to NLGI 2. These metering devices are characterized by Metering quantity non-adjustable: 0,1 to 1,3 cm 3 /min

an innovative, compact and sturdy design with SKF Quick Connector 0.006 to 0.079 in 3 / min

adjustable: 0,1 to 1,1 cm 3 /min

systems.

0.006 to 0.067 in 3 / min

Lubricant fluid greases and grease NLGI 0, 1, 2

Operating temperature –25 to +80 °C; –13 to +176 °F

Features and benefits Operating pressure 100 to 315 bar; 1 450 to 4 570 psi

Relief pressure 30 or 70 bar; 435 or 1 015 psi

• Innovative, extremely compact design Materials anodized aluminum, stainless steel,

• Optional metering devices for 1 to 12 ports FKM (FPM)

Connection main line G 1 /4 for pipes 4 or 6 mm

to match number of lubrication points 0.16 or 0.24 in

• Metering nipples with indicator pin for visual Connection outlet G 1 /8 for pipes 4 or 6 mm,

0.16 or 0.24 in

monitoring of each lubrication point Lubricant point solderless pipe connection (DIN 3862)

Dimensions depending on model:

• Optional push-in type or screw-in type fittings

min. 97 × 130 × 54 mm;

for feed line or main line connections are selectable max. 281 × 121 × 119 mm;

min. 3.82 × 5.12 × 2.13 in

• Easy metering adjustment by replacing the metering nipples

max. 11.06 × 4.76 × 4.68 in

• Black anodized surface for optimized corrosion protection Mounting position any

• Suitable for corrosivity category C3 and C5 per

DIN EN ISO 12944 and certified by Germanischer Loyd

• High functional reliability when using stiff greases

at low working temperatures

Applications

NOTE

• Onshore and offshore wind energy systems Further technical information, technical drawings,

• Construction machinery accessories, spare parts or product function descriptions

available on SKF.com/lubrication:

• Steel industry

1-5001-EN, 951-230-007

• Heavy industry

3D

• General mechanical engineering applications

skf-lubrication partcommunity com/3d-cad-models

140