Page 138 - Single-line automatic lubrication systems

P. 138

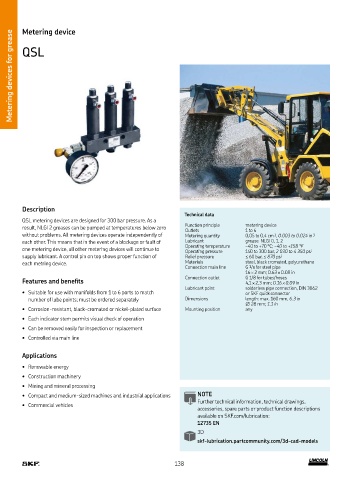

Metering devices for grease Metering device

QSL

Description

Technical data

QSL metering devices are designed for 300 bar pressure. As a

result, NLGI 2 greases can be pumped at temperatures below zero Function principle metering device

Outlets

1 to 6

without problems. All metering devices operate independently of Metering quantity 0,05 to 0,4 cm 3 , 0.003 to 0.024 in 3

each other. This means that in the event of a blockage or fault of Lubricant grease NLGI 0, 1, 2

Operating temperature –40 to +70 °C; –40 to +158 °F

one metering device, all other metering devices will continue to

Operating pressure 140 to 300 bar, 2 030 to 4 350 psi

supply lubricant. A control pin on top shows proper function of Relief pressure ≤ 60 bar, ≤ 870 psi

each metring device. Materials steel, black cromated, polyurethane

Connection main line G 3 /8 for steel pipe

16 × 2 mm; 0.63 × 0.08 in

Connection outlet G 1/8 for tubes/hoses

Features and benefits 4,1 × 2,3 mm; 0.16 × 0.09 in

Lubricant point solderless pipe connection, DIN 3862

• Suitable for use with manifolds from 1 to 6 ports to match or SKF quick connector

number of lube points; must be ordered separately Dimensions length: max. 160 mm, 6.3 in

∅ 28 mm; 1.1 in

• Corrosion-resistant, black-cromated or nickel-plated surface Mounting position any

• Each indicator stem permits visual check of operation

• Can be removed easily for inspection or replacement

• Controlled via main line

Applications

• Renewable energy

• Construction machinery

• Mining and mineral processing

• Compact and medium-sized machines and industrial applications NOTE

Further technical information, technical drawings,

• Commercial vehicles

accessories, spare parts or product function descriptions

available on SKF.com/lubrication:

12735 EN

3D

skf-lubrication partcommunity com/3d-cad-models

138