Page 143 - Single-line automatic lubrication systems

P. 143

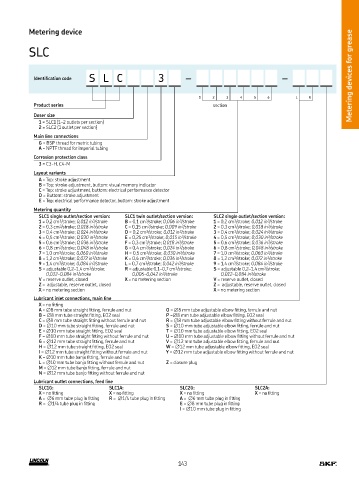

Metering device

Metering devices for grease

SLC

S L C 3 – –

Identification code

1 2 3 4 5 6 L R

Product series section

Doser size

1 = SLC1 (1–2 outlets per section)

2 = SLC2 (1 outlet per section)

Main line connections

G = BSP thread for metric tubing

A = NPTF thread for imperial tubing

Corrosion protection class

3 = C3-H, C4-M

Layout variants

A = Top: stroke adjustment

B = Top: stroke adjustment, buttom: visual memory indicator

C = Top: stroke adjustment, buttom: electrical performance detector

D = Buttom: stroke adjustment

E = Top: electrical performance detector, buttom: stroke adjustment

Metering quantity

SLC1 single outlet/section version: SLC1 twin outlet/section version: SLC2 single outlet/section version:

1 = 0,2 cm 3 /stroke; 0,012 in 3 /stroke B = 0,1 cm 3 /stroke; 0,006 in 3 /stroke 1 = 0,2 cm 3 /stroke; 0,012 in 3 /stroke

2 = 0,3 cm 3 /stroke; 0,018 in 3 /stroke C = 0,15 cm 3 /stroke; 0,009 in 3 /stroke 2 = 0,3 cm 3 /stroke; 0,018 in 3 /stroke

3 = 0,4 cm 3 /stroke; 0,024 in 3 /stroke D = 0,2 cm 3 /stroke; 0,012 in 3 /stroke 3 = 0,4 cm 3 /stroke; 0,024 in 3 /stroke

4 = 0,5 cm 3 /stroke; 0,030 in 3 /stroke E = 0,25 cm 3 /stroke; 0,015 in 3 /stroke 4 = 0,5 cm 3 /stroke; 0,030 in 3 /stroke

5 = 0,6 cm 3 /stroke; 0,036 in 3 /stroke F = 0,3 cm 3 /stroke; 0,018 in 3 /stroke 5 = 0,6 cm 3 /stroke; 0,036 in 3 /stroke

6 = 0,8 cm 3 /stroke; 0,048 in 3 /stroke G = 0,4 cm 3 /stroke; 0,024 in 3 /stroke 6 = 0,8 cm 3 /stroke; 0,048 in 3 /stroke

7 = 1,0 cm 3 /stroke; 0,060 in 3 /stroke H = 0,5 cm 3 /stroke; 0,030 in 3 /stroke 7 = 1,0 cm 3 /stroke; 0,060 in 3 /stroke

8 = 1,2 cm 3 /stroke; 0,072 in 3 /stroke K = 0,6 cm 3 /stroke; 0,036 in 3 /stroke 8 = 1,2 cm 3 /stroke; 0,072 in 3 /stroke

9 = 1,4 cm 3 /stroke; 0,084 in 3 /stroke L = 0,7 cm 3 /stroke; 0,042 in 3 /stroke 9 = 1,4 cm 3 /stroke; 0,084 in 3 /stroke

S = adjustable 0,2–1,4 cm 3 /stroke; R = adjustable 0,1–0,7 cm 3 /stroke; S = adjustable 0,2–1,4 cm 3 /stroke;

0,012–0,084 in 3 /stroke 0,006–0,042 in 3 /stroke 0,012–0,084 in 3 /stroke

V = reserve outlet, closed X = no metering section V = reserve outlet, closed

Z = adjustable, reserve outlet, closed Z = adjustable, reserve outlet, closed

X = no metering section X = no metering section

Lubricant inlet connections, main line

X = no fitting

A = ∅8 mm tube straight fitting, ferrule and nut O = ∅8 mm tube adjustable elbow fitting, ferrule and nut

B = ∅8 mm tube straight fitting, EO2 seal P =∅8 mm tube adjustable elbow fitting, EO2 seal

C = ∅8 mm tube straight fitting without ferrule and nut R = ∅8 mm tube adjustable elbow fitting without ferrule and nut

D = ∅10 mm tube straight fitting, ferrule and nut S = ∅10 mm tube adjustable elbow fitting, ferrule and nut

E = ∅10 mm tube straight fitting, EO2 seal T = ∅10 mm tube adjustable elbow fitting, EO2 seal

F = ∅10 mm tube straight fitting without ferrule and nut U = ∅10 mm tube adjustable elbow fitting without ferrule and nut

G = ∅12 mm tube straight fitting, ferrule and nut V = ∅12 mm tube adjustable elbow fitting, ferrule and nut

H = ∅12 mm tube straight fitting, EO2 seal W = ∅12 mm tube adjustable elbow fitting, EO2 seal

I = ∅12 mm tube straight fitting without ferrule and nut Y = ∅12 mm tube adjustable elbow fitting without ferrule and nut

K = ∅10 mm tube banjo fitting, ferrule and nut

L = ∅10 mm tube banjo fitting without ferrule and nut Z = closure plug

M = ∅12 mm tube banjo fitting, ferrule and nut

N = ∅12 mm tube banjo fitting without ferrule and nut

Lubricant outlet connections, feed line

SLC1G: SLC1A: SLC2G: SLC2A:

X = no fitting X = no fitting X = no fitting X = no fitting

A = ∅6 mm tube plug in fitting R = ∅1/4 tube plug in fitting A = ∅6 mm tube plug in fitting

R = ∅1/4 tube plug in fitting E = ∅8 mm tube plug in fitting

I = ∅10 mm tube plug in fitting

143