Page 222 - Rollingbearings

P. 222

Bearing execution Overall conclusions

• The 22328 CCJA/W33VA405 bearing meets the rating life

requirement.

The bearing selected for this application is a spherical roller bearing • SKF grease LGEP2 is appropriate for the given operating

for vibratory applications (Designs and variants page 775). conditions.

These bearings are identiied by the designation sufixes VA405 • Maintenance and condition monitoring aspects have not been

and VA406. They have a C4 internal clearance, which is required included in this example. For additional information about SKF

because of the interference it of the outer ring in combination with offers for vibrating screens, refer to the information on the SKF

the temperature difference between inner and outer rings, particu- website under Industry Solutions.

larly during start-up situations. Their hardened window-type cages

reduce friction and wear in the bearing when operating under rotat-

ing outer ring load and high acceleration conditions, resulting in a

lower operating temperature and longer lubricant life.

The VA406 execution is intended for the non-locating support and

has a PTFE coated bore. This helps to prevent fretting corrosion,

which can occur because of the loose it and vibration.

Sealing, mounting and

dismounting

Vibrating screen designs generally use labyrinth seals to protect the

rolling bearings. With this type of seal, it is important to maintain a

suficient quantity of grease in the labyrinth gaps so that dirt and

moisture are kept away from the bearings. Quantities and relubrication

intervals should be adjusted according to the operator's observations.

Check the total radial run-out of the housing seat when the housing

is mounted to the screen frame. Inadmissible deformation might

occur and can require corrective action.

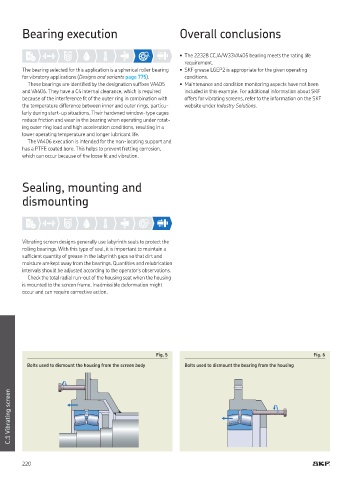

Fig. 5 Fig. 6

Bolts used to dismount the housing from the screen body Bolts used to dismount the bearing from the housing

C.1 Vibrating screen

220