Page 221 - Rollingbearings

P. 221

Bearing interfaces

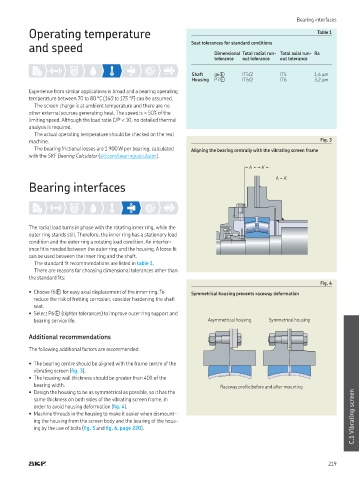

Operating temperature Table 1

and speed Seat tolerances for standard conditions

Dimensional Total radial run- Total axial run- Ra

tolerance out tolerance out tolerance

Shaft g6� IT5/2 IT5 1,6 µm

Housing P7� IT6/2 IT6 3,2 µm

Experience from similar applications is broad and a bearing operating

temperature between 70 to 80 °C (160 to 175 °F) can be assumed.

The screen charge is at ambient temperature and there are no

other external sources generating heat. The speed is < 50% of the

limiting speed. Although the load ratio C/P < 10, no detailed thermal

analysis is required.

The actual operating temperature should be checked on the real

machine. Fig. 3

The bearing frictional losses are 1 900 W per bearing, calculated Aligning the bearing centrally with the vibrating screen frame

with the SKF Bearing Calculator (skf.com/bearingcalculator).

A ` A

A = A´

Bearing interfaces

The radial load turns in phase with the rotating inner ring, while the

outer ring stands still. Therefore, the inner ring has a stationary load

condition and the outer ring a rotating load condition. An interfer-

ence it is needed between the outer ring and the housing. A loose it

can be used between the inner ring and the shaft.

The standard it recommendations are listed in table 1.

There are reasons for choosing dimensional tolerances other than

the standard its:

Fig. 4

• Choose f6� for easy axial displacement of the inner ring. To Symmetrical housing prevents raceway deformation

reduce the risk of fretting corrosion, consider hardening the shaft

seat.

• Select P6� (tighter tolerances) to improve outer ring support and

bearing service life. Asymmetrical housing Symmetrical housing

Additional recommendations

The following additional factors are recommended:

• The bearing centre should be aligned with the frame centre of the

vibrating screen (ig. 3).

• The housing wall thickness should be greater than 40% of the

bearing width. Raceway proile before and after mounting

• Design the housing to be as symmetrical as possible, so it has the

same thickness on both sides of the vibrating screen frame, in

order to avoid housing deformation (ig. 4).

• Machine threads in the housing to make it easier when dismount- C.1 Vibrating screen

ing the housing from the screen body and the bearing of the hous-

ing by the use of bolts (ig. 5 and ig. 6, page 220).

219