Page 135 - Rollingbearings

P. 135

Estimating bearing operating temperature

Starting torque Estimating heat

dissipation from SKF

The starting torque of a rolling bearing is

deined as the frictional moment that must plummer (pillow)

be overcome by the bearing to start rotating,

at an ambient temperature of 20 to 30 °C blocks

(70 to 85 °F) Therefore, only the sliding fric-

tional moment and the frictional moment of For SKF plummer (pillow) block housings,

seals, if applied, are taken into consideration you can use a model based on bearing size

to estimate heat dissipation values

M start = M + M seal Using diagram 4, you can estimate the

sl

heat dissipation per degree above ambient

temperature, W , for a bearing with bearing

s

where mean diameter d in a plummer block hous-

m

M start = starting frictional moment [Nmm] ing, with the shaft exposed to the surround-

M = sliding frictional moment [Nmm] ing air

sl

M seal = frictional moment of the seals [Nmm] The estimation is valid for SKF plummer

block housings used with grease or oil bath

We recommend using the SKF Bearing lubrication and only where there is no signif-

Calculator (skf com/bearingcalculator) for icant heat input from external sources, such

calculating starting torque values as steam heating of shafts or pronounced

radiation from hot surfaces

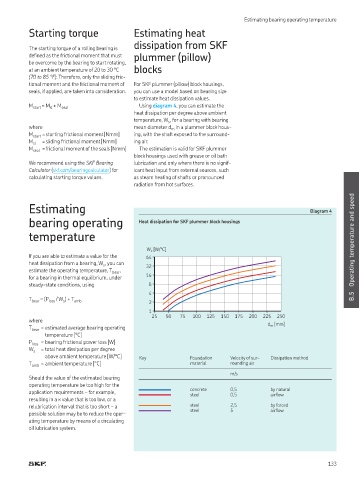

Estimating Diagram 4

bearing operating Heat dissipation for SKF plummer block housings

temperature Operating temperature and speed

W s [W/°C]

If you are able to estimate a value for the 64

heat dissipation from a bearing, W , you can 32

s

estimate the operating temperature, T bear ,

for a bearing in thermal equilibrium, under 16

steady-state conditions, using 8

4 B.5

T bear = (P loss / W ) + T amb 2

s

1

25 50 75 100 125 150 175 200 225 250

where

d m [mm]

T bear = estimated average bearing operating

temperature [°C]

P loss = bearing frictional power loss [W]

W = total heat dissipation per degree

s

above ambient temperature [W/°C] Key Foundation Velocity of sur- Dissipation method

T amb = ambient temperature [°C] material rounding air

m/s

Should the value of the estimated bearing

operating temperature be too high for the

application requirements – for example, concrete 0,5 by natural

steel

0,5

airlow

resulting in a κ value that is too low, or a

relubrication interval that is too short – a steel 2,5 by forced

steel 5 airlow

possible solution may be to reduce the oper-

ating temperature by means of a circulating

oil lubrication system

133