Page 266 - EMUGE

P. 266

Gewindebohrer · Taps

Product

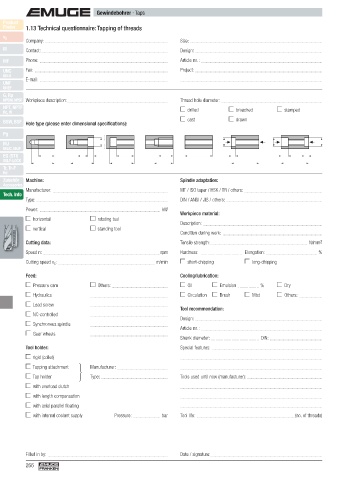

Finder 1.13 Technical questionnaire: Tapping of threads

v c

Company: ..................................................................................................................................................... Size: .................................................................................................................................................................

M

Contact: .......................................................................................................................................................... Design: ...........................................................................................................................................................

MF Phone: ............................................................................................................................................................ Article no.: ...................................................................................................................................................

UNC Fax: .................................................................................................................................................................. Project: ...........................................................................................................................................................

UN-8

E-mail: ............................................................................................................................................................ .............................................................................................................................................................................

UNF

UNEF

G, Rp

NPSM, NPSF Workpiece description: .......................................................................................................................... Thread hole diameter: ...........................................................................................................................

NPT, NPTF drilled broached stamped

Rc, W

cast drawn

BSW, BSF Hole type (please enter dimensional specifi cations):

Pg

MJ

UNJC, UNJF

EG (STI)

SELF-LOCK

Tr, Tr-F

Rd

Zubehör Machine: Spindle adaptation:

Accessories

Manufacturer: ............................................................................................................................................ MT / ISO taper / HSK / TR / others: ...............................................................................................

Tech. Info

Type: ................................................................................................................................................................ DIN / ANSI / JIS / others: .....................................................................................................................

Power: ................................................................................................................................................... kW

Workpiece material:

horizontal rotating tool

Description: .................................................................................................................................................

vertical standing tool

Condition during work: .........................................................................................................................

Cutting data: Tensile strength: ...................................................................................................................... N/mm 2

Speed n: ...............................................................................................................................................rpm Hardness: ……………………………… Elongation: .............................................................. %

Cutting speed v c : ..................................................................................................................... m/min short-chipping long-chipping

Feed: Cooling/lubrication:

Pressure cam Others: .................................................................... Oil Emulsion ……………… % Dry

Hydraulics .............................................................................................. Circulation Brush Mist Others: ............................

Lead screw ..............................................................................................

Tool recommendation:

NC-controlled ..............................................................................................

Design: ...........................................................................................................................................................

Synchronous spindle ..............................................................................................

Article no.: ...................................................................................................................................................

Gear wheels ..............................................................................................

Shank diameter: …………………………………… DIN: ................................................................

Tool holder: Special features: ......................................................................................................................................

rigid (collet) .............................................................................................................................................................................

Tapping attachment ⎫ Manufacturer: ............................................................. .............................................................................................................................................................................

⎬

Tap holder ⎭ Type: ................................................................................. Tools used until now (manufacturer): ...........................................................................................

with overload clutch .............................................................................................................................................................................

with length compensation .............................................................................................................................................................................

with axial parallel fl oating .............................................................................................................................................................................

with internal coolant supply Pressure: ................................. bar Tool life: ........................................................................................................................(no. of threads)

Filled in by: .................................................................................................................................................. Date / signature: ........................................................................................................................................

266