Page 42 - Y-bearing-units

P. 42

Design of Y-bearing

arrangements

Axial displacement

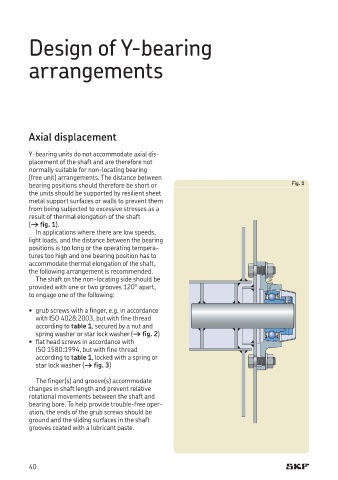

Y-bearing units do not accommodate axial dis-

placement of the shaft and are therefore not

normally suitable for non-locating bearing

(free unit) arrangements. The distance between

bearing positions should therefore be short or Fig. 1

the units should be supported by resilient sheet

metal support surfaces or walls to prevent them

from being subjected to excessive stresses as a

result of thermal elongation of the shaft

(† fig. 1).

In applications where there are low speeds,

light loads, and the distance between the bearing

positions is too long or the operating tempera-

tures too high and one bearing position has to

accommodate thermal elongation of the shaft,

the following arrangement is recommended.

The shaft on the non-locating side should be

provided with one or two grooves 120° apart,

to engage one of the following:

• grub screws with a finger, e.g. in accordance

with ISO 4028:2003, but with fine thread

according to table 1, secured by a nut and

spring washer or star lock washer († fig. 2)

• flat head screws in accordance with

ISO 1580:1994, but with fine thread

according to table 1, locked with a spring or

star lock washer († fig. 3)

The finger(s) and groove(s) accommodate

changes in shaft length and prevent relative

rotational movements between the shaft and

bearing bore. To help provide trouble-free oper-

ation, the ends of the grub screws should be

ground and the sliding surfaces in the shaft

grooves coated with a lubricant paste.

40