Page 89 - Rollingbearings

P. 89

These selection criteria and the related Note that there are applications where both

bearing ratings and static safety factor are selection criteria must be considered, for

shown in diagram 2 and are described in example where a duty cycle has occasional

detail in the relevant subsections peak loads Also, in applications where the

Which selection criteria you should use bearing is lightly loaded, the minimum load

depends on the operating conditions of the requirement (Requisite minimum load,

bearing: page 106) must also be considered

After determining bearing size, and before

• For applications where bearings are run going to the next step, check the items listed

ning in typical operating conditions – i e in Checklist after the bearing size is deter-

normal speeds, good lubrication condi mined, page 106.

tions and not highly or peak loaded – use Other attributes of the bearing compon

Size selection based on rating life, ents, such as strength and suitability, are

page 88 addressed elsewhere in the Bearing selection

• For applications where bearings are run process, including Lubrication, page 110,

ning under very low speeds or which are and Bearing execution, page 182, as well as

used under stationary conditions, very bad in the product sections Consider these

lubrication conditions or where occasional attributes, in addition to bearing size, to

peak loads occur, use Size selection based ensure you obtain best bearing

on static load, page 104 performance

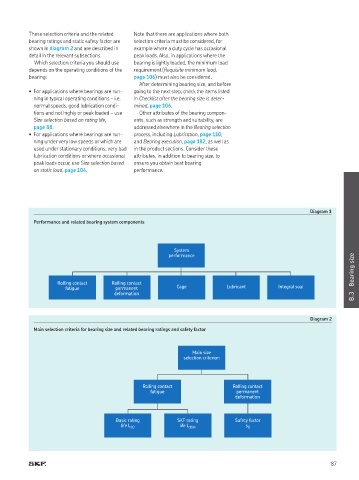

Diagram 1

Performance and related bearing system components

System

Bearing size

performance

Rolling contact Rolling contact

fatigue permanent Cage Lubricant Integral seal

B.3

deformation

Diagram 2

Main selection criteria for bearing size and related bearing ratings and safety factor

Main size

selection criterion

Rolling contact Rolling contact

fatigue permanent

deformation

Basic rating SKF rating Safety factor

life L 10 life L 10m s 0

87