Page 351 - Rollingbearings

P. 351

Lubrication

If relubrication is needed, the relubrication The following bearings do not have the Table 3

intervals can be estimated by following the standard relubrication features:

Bearing mean diameter d m

method explained under Estimating the relu-

brication interval for grease, page 111 • Stainless steel insert bearings with grub

When relubricating, the shaft should be screws have a lubrication groove in the

turned and the grease pumped slowly until outer ring located on the side opposite the 2

fresh grease starts to escape from the locking device and one lubrication hole d m

seal(s) Excessive pressure from pumping within this groove

too quickly can damage the seals When • Insert bearings with a standard inner ring

machines and equipment are used for a without designation sufix B and insert

limited period of time, SKF recommends bearings with 5-lip seals are lubricated for

relubricating each bearing at the end of the life and cannot be relubricated They do

operational period, i e immediately before not have any lubrication holes Bearing size 1) Bearing mean diameter

being laid up d m

– mm

Relubrication features

03 28,5

SKF insert bearings are designed to facilitate 04 33,5

relubrication They have two lubrication 05 39

holes in the outer ring as standard, one on

06 46

each side, positioned 120° apart Bearings 07 53,5

without lubrication holes can be supplied on 08 60

request (designation sufix W) 09 65

10 70

11 77,5

12 85

13 92,5

14 97,5

15 102,5

16 110

17 117,5

18 126

20 141

Diagram 1

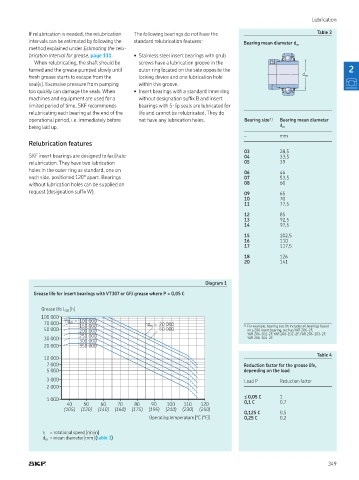

Grease life for insert bearings with VT307 or GFJ grease where P = 0,05 C

Grease life L [h]

10

100 000

nd m = 100 000

70 000 150 000 nd m = 20 000 1) For example, bearing size 06 includes all bearings based

50 000 200 000 50 000 on a 206 insert bearing, such as YAR 206-2F,

250 000 YAR 206-101-2F, YAR 206-102-2F, YAR 206-103-2F,

30 000 YAR 206-104-2F

300 000

20 000 350 000

Table 4

10 000

7 000 Reduction factor for the grease life,

5 000 depending on the load

3 000 Load P Reduction factor

2 000

≤ 0,05 C 1

1 000

40 50 60 70 80 90 100 110 120 0,1 C 0,7

(105) (120) (140) (160) (175) (195) (210) (230) (250)

0,125 C 0,5

Operating temperature [°C (°F)] 0,25 C 0,2

n = rotational speed [r/min]

d = mean diameter [mm] (table 3)

m

349