Page 350 - Rollingbearings

P. 350

2 Insert bearings (Y-bearings)

Lubrication Grease life for insert Relubrication

bearings Insert bearings do not need relubrication if

SKF insert bearings are supplied capped on the grease life exceeds the SKF rating life,

both sides and are greased • is presented as L , i e the time period at page 89 of the bearing

10

2 the end of which 90% of the bearings are Relubrication can extend bearing service

still reliably lubricated life under any of the following conditions:

• depends on the load, operating tempera-

Greases for capped ture and the nd value (diagram 1) • The bearings are exposed to high humidity

m

bearings The indicated grease life is valid for the fol- • The bearings accommodate normal or

or severe contamination

lowing combination of operating conditions: heavy loads

Insert bearings are illed with one of the • The bearings operate for extended periods

following greases (table 2): • horizontal shaft at high speeds or at temperatures above

• very light to moderate loads (P ≤ 0,05 C) 55 °C (130 °F)

• zinc-coated and stainless steel insert • stationary machine • The bearings are subjected to high vibration

bearings • low vibration levels levels

† food-grade grease GFJ, registered by

NSF as category H1 Where the operating conditions vary, the To relubricate insert bearings, the following

The NSF registration conirms the grease life obtained from the diagram should greases can be used:

grease fulils the requirements listed in the be adjusted as follows:

US Food and Drug Administration’s guide- • zinc-coated and stainless steel insert

lines under 21 CFR section 178 3570 • vertical shafts † 50% of the obtained value bearings

(lubricant acceptable with incidental food • heavier loads (P > 0,05 C) † apply reduction † food-grade grease SKF LGFP 2

contact, for use in and around food pro- factor (table 4) • all other insert bearings

cessing areas) † SKF LGWA 2, LGMT 2 or LGMT 3 grease

• all other insert bearings The values for adjusting the grease life are

† standard grease VT307 estimates Vibration can have a negative

inluence on grease life The extent cannot

be quantiied, and the inluence increases

with increasing operating temperature

Table 2

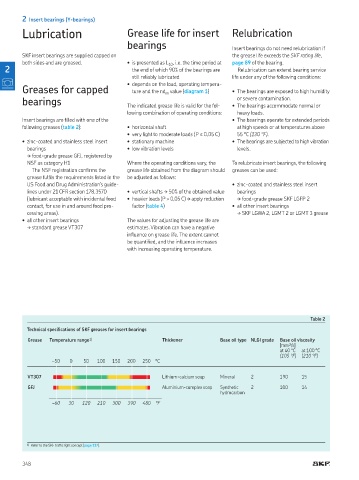

Technical speciications of SKF greases for insert bearings

Grease Temperature range 1) Thickener Base oil type NLGI grade Base oil viscosity

[mm 2 /s]

at 40 °C at 100 °C

(105 °F) (210 °F)

–50 0 50 100 150 200 250 °C

VT307 Lithium-calcium soap Mineral 2 190 15

GFJ Aluminium-complex soap Synthetic 2 100 14

hydrocarbon

–60 30 120 210 300 390 480 °F

1) Refer to the SKF trafic light concept (page 117)

348