Page 230 - Rollingbearings

P. 230

Centrifugal pump

C.3 Centrifugal pump

Performance and operating

This example shows the bearing selection process applied to an

application case in which modiication is required to a centrifugal

pump. conditions

The pump manufacturer wants to improve the eficiency of an

existing centrifugal process pump by modifying the impeller. As a

result, the bearing loads will be greater, and so the current bearing

selection needs to be checked to verify that it can cope with the

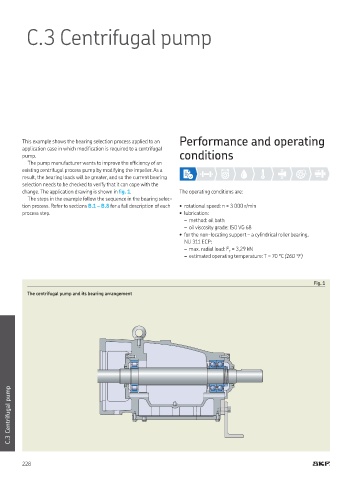

change. The application drawing is shown in ig. 1. The operating conditions are:

The steps in the example follow the sequence in the bearing selec-

tion process. Refer to sections B.1 – B.8 for a full description of each • rotational speed: n = 3 000 r/min

process step. • lubrication:

– method: oil bath

– oil viscosity grade: ISO VG 68

• for the non-locating support – a cylindrical roller bearing,

NU 311 ECP:

– max. radial load: F = 3,29 kN

r

– estimated operating temperature: T = 70 °C (160 °F)

Fig. 1

The centrifugal pump and its bearing arrangement

C.3 Centrifugal pump

228