Page 254 - Y-bearing-units

P. 254

SKF Food Line Y-bearing units

To meet the requirements of the food, beverage The sealing arrangement, proven to be highly

and pharmaceutical processing industries, SKF effective during washdowns, consists of a stain-

has developed a special range of Y-bearing units. less steel supported, grease filled, multi-lip FDA

The housings for SKF Food Line Y-bearing approved synthetic rubber contacting and laby-

units are made of three different materials: rinth seal with a stainless steel flinger. († fig. 1).

The SKF Food Line Y-bearing units are

• Composite with dedicated rugged design pre-lubricated for life with a non-toxic food-

• Cast stainless steel for heavy-duty grade grease, based on a PAO oil and an

applications aluminium-complex soap as a thickener (food

• Zinc-coated cast iron for a cost-effective solution industry approved NSF H1).

The units are equipped with Y-bearings made of

stainless steel (YAR 2-2RF/HV series) or of high Designs

quality, carbon chromium steel with zinc coated

inner and outer rings (YAR 2-2RF/VE495 series). SKF Food Line Y-bearing units with

The bearing inner rings are extended on both composite housings

sides and are locked on the shaft with grub screws.

Strong, lightweight, chemical resistant

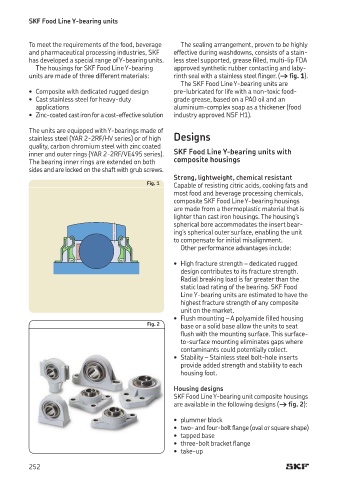

Fig. 1 Capable of resisting citric acids, cooking fats and

most food and beverage processing chemicals,

composite SKF Food Line Y-bearing housings

are made from a thermoplastic material that is

lighter than cast iron housings. The housing’s

spherical bore accommodates the insert bear-

ing’s spherical outer surface, enabling the unit

to compensate for initial misalignment.

Other performance advantages include:

• High fracture strength – dedicated rugged

design contributes to its fracture strength.

Radial breaking load is far greater than the

static load rating of the bearing. SKF Food

Line Y-bearing units are estimated to have the

highest fracture strength of any composite

unit on the market.

• Flush mounting – A polyamide filled housing

Fig. 2 base or a solid base allow the units to seat

flush with the mounting surface. This surface-

to-surface mounting eliminates gaps where

contaminants could potentially collect.

• Stability – Stainless steel bolt-hole inserts

provide added strength and stability to each

housing foot.

Housing designs

SKF Food Line Y-bearing unit composite housings

are available in the following designs († fig. 2):

• plummer block

• two- and four-bolt flange (oval or square shape)

• tapped base

• three-bolt bracket flange

• take-up

252