Page 46 - SKF-bearing-housings

P. 46

SKF bearing housings – overview, selection and application recommendations

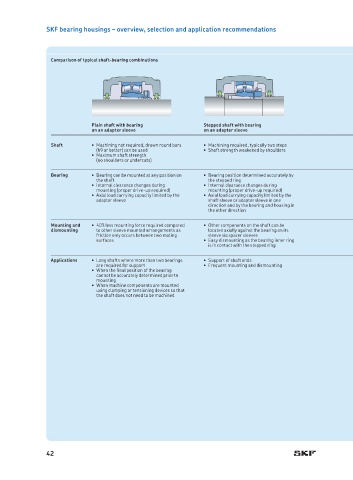

Comparison of typical shaft-bearing combinations

Plain shaft with bearing Stepped shaft with bearing

on an adapter sleeve on an adapter sleeve

Shaft • Machining not required, drawn round bars • M achining required, typically two steps • •

(h9 or better) can be used • Shaft strength weakened by shoulders • •

• Maximum shaft strength •

(no shoulders or undercuts)

Bearing • Bearing can be mounted at any position on • Bearing position determined accurately by • •

the shaft the stepped ring

• Internal clearance changes during • Internal clearance changes during • •

mounting (proper drive-up required) mounting (proper drive-up required)

• Axial load carrying capacity limited by the • Axial load carrying capacity limited by the • •

adapter sleeve shaft sleeve or adapter sleeve in one

direction and by the bearing and housing in

the other direction

Mounting and • 40% less mounting force required compared • Other components on the shaft can be • •

dismounting to other sleeve mounted arrangements as located axially against the bearing on its

friction only occurs between two mating sleeve via spacer sleeves •

surfaces • Easy dismounting as the bearing inner ring •

is in contact with the stepped ring •

Applications • Long shafts where more than two bearings • Support of shaft ends • •

are required for support • Frequent mounting and dismounting • •

• When the final position of the bearing •

cannot be accurately determined prior to

mounting

• When machine components are mounted

using clamping or tensioning devices so that

the shaft does not need to be machined

42