Page 32 - SKF-bearing-housings

P. 32

SKF bearing housings – overview, selection and application recommendations

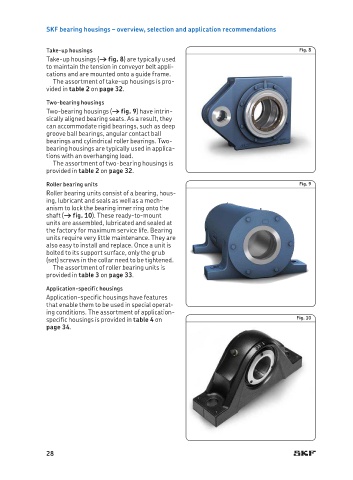

Take-up housings Fig. 8

Take-up housings († fig. 8) are typically used

to maintain the tension in conveyor belt appli-

cations and are mounted onto a guide frame.

The assortment of take-up housings is pro-

vided in table 2 on page 32.

Two-bearing housings

Two-bearing housings († fig. 9) have intrin-

sically aligned bearing seats. As a result, they

can accommodate rigid bearings, such as deep

groove ball bearings, angular contact ball

bearings and cylindrical roller bearings. Two-

bearing housings are typically used in applica-

tions with an overhanging load.

The assortment of two-bearing housings is

provided in table 2 on page 32.

Roller bearing units Fig. 9

Roller bearing units consist of a bearing, hous-

ing, lubricant and seals as well as a mech-

anism to lock the bearing inner ring onto the

shaft († fig. 10). These ready-to-mount

units are assembled, lubricated and sealed at

the factory for maximum service life. Bearing

units require very little maintenance. They are

also easy to install and replace. Once a unit is

bolted to its support surface, only the grub

(set) screws in the collar need to be tightened.

The assortment of roller bearing units is

provided in table 3 on page 33.

Application-specific housings

Application-specific housings have features

that enable them to be used in special operat-

ing conditions. The assortment of application-

specific housings is provided in table 4 on Fig. 10

page 34.

28