Page 44 - Multi-line-automatic

P. 44

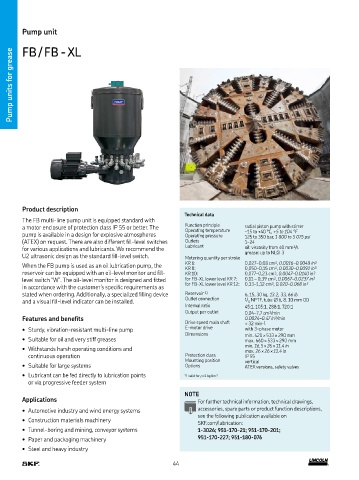

Pump unit

FB / FB - XL

Pump units for grease

Product description

Technical data

The FB multi-line pump unit is equipped standard with

a motor enclosure of protection class IP 55 or better The Function principle radial piston pump with stirrer

Operating temperature

pump is available in a design for explosive atmospheres Operating pressure –15 to +40 °C, +5 to 104 °F

125 to 350 bar, 1 800 to 5 075 psi

(ATEX) on request There are also different fill-level switches Outlets 1–24

for various applications and lubricants We recommend the Lubricant oil: viscosity from 40 mm 3 /s

U2 ultrasonic design as the standard fill-level switch Metering quantity per stroke grease: up to NLGI 3

KR 6: 0,027–0,08 cm 3 , 0.0016–0.0048 in 3

When the FB pump is used as an oil lubrication pump, the KR 8: 0,050–0,15 cm 3 , 0.0030–0.0091 in 3

reservoir can be equipped with an oil-level monitor and fill- KR 10: 0,077–0,23 cm 3 , 0.0047–0.0140 in 3

level switch “W” The oil-level monitor is designed and fitted for FB-XL lower level KR 7: 0,11 – 0,39 cm 3 , 0.0067–0.0237 in 3

in accordance with the customer’s specific requirements as for FB-XL lower level KR 12: 0,33–1,12 cm 3 , 0.020–0.068 in 3

stated when ordering Additionally, a specialized filling device Reservoir 1) 6, 15, 30 kg, 13.2, 33, 66 lb

and a visual fill-level indicator can be installed Outlet connection 1 / NPTF, tube ∅ 6, 8, 10 mm OD

4

Internal ratio 45:1, 105:1, 288:1, 720:1

Output per outlet 0,04–7,7 cm 3 /min

Features and benefits 0.0024–0.47 in 3 /min

Drive speed main shaft < 32 min -1

• Sturdy, vibration-resistant multi-line pump E-motor drive with 3-phase motor

Dimensions min 420 × 533 × 290 mm

• Suitable for oil and very stiff greases max 660 × 533 × 290 mm

min. 16.5 × 26 × 11.4 in

• Withstands harsh operating conditions and max. 26 × 26 × 11.4 in

continuous operation Protection class IP 55

Mounting position vertical

• Suitable for large systems Options ATEX versions, safety valves

• Lubricant can be fed directly to lubrication points 1) valid for ρ=1 kg/dm 3

or via progressive feeder system

NOTE

Applications For further technical information, technical drawings,

• Automotive industry and wind energy systems accessories, spare parts or product function descriptions,

see the following publication available on

• Construction materials machinery

SKF com/lubrication:

• Tunnel-boring and mining, conveyor systems 1-3026; 951-170-21; 951-170-201;

• Paper and packaging machinery 951-170-227; 951-180-076

• Steel and heavy industry

44